- Software - Simulation

- Software

- Test software

- WFL MILLTURN TECHNOLOGIES GMBH & CO KG

- Products

- Catalogs

- News & Trends

- Exhibitions

Control software CrashGuard Studio®testmeasurementcalculation

Add to favorites

Compare this product

Characteristics

- Function

- control, test, measurement, calculation, CAD/CAM, simulation, programming, process, machining

- Applications

- for aeronautics

- Type

- 3D

Description

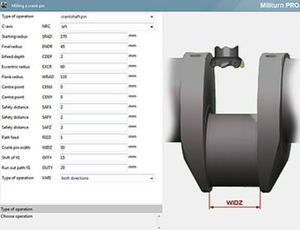

The most effective way to test and optimise new or modified CNC programs is through the use of the 3D simulation software CrashGuard Studio. These tests can be carried out at an external programming station or directly on the machine control system. By optimising the machining process and ensuring faults are corrected early, users can expect a significant reduction in the risk of collisions and scrap, while also minimising unproductive downtimes. This unlocks new potential and offers clear competitive advantages.

CrashGuard Studio is the perfect addition to any CAD/CAM software, as well as to the WFL collision prevention software CrashGuard. With the help of material removal simulation, 3D geometries of workpieces can be exported in any machining state. The data for workpieces, tools and clamping devices can be transferred as required.

Benefits of CrashGuard Studio

Complete and true-to-life simulation of NC programs with material removal directly via the programming station or machine control system

Shorter run-in time for the machine, thus significantly increasing productivity

Realistic calculation of machining time

Optimisation of the entire machining process and reduction in the risk of scrap

Increase in efficiency thanks to early error detection

Different machining units such as counter spindles or bottom slides can be aligned in a time-efficient manner Unproductive downtimes can be reduced to a minimum

Simulation of all cycles possible (whether from WFL or created by the customer)

Integrated 3D measurement functions for optimal configuration of tools

Perfect compatibility with and ideal addition to all CAD/CAM systems

Training tool for programmers and operators

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other WFL MILLTURN TECHNOLOGIES GMBH & CO KG products

SOFTWARE

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.