X-ray inspection machine XRH433 Towersurfacefor NDT

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Technology

- X-ray

- Applications

- surface, for NDT

Description

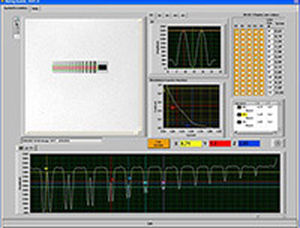

The XRH433 Tower is a versatile system for high precision double-wall weld inspection. The system contains of five CNC programmable axes and a simulated C arm to ensure a perpendicular setup. Especially the big magnification axis allows high quality micro-focus inspection.

A special feature is the high repetition accuracy and the capability of advanced inspection processes like Automated Defect Recognition (ADR) and Computed Tomography (CT). As an image source CR-plates, digital detectors or film can be chosen freely depending on the requirements and a rod-anode for butt-weld inspection can be added.

Customized to provide an inspection workflow with highest efficiency

Designed for high accuracy micro-focus inspection of aerospace pipes

Flexible choice between multiple image sources (DR, CR, RT)

Can be tailored towards specific inspection requirements and parts

Approved through reference installations in the aerospace industry

VIDEO

Catalogs

XRH 433 Tower

1 Pages

Related Searches

- Inspection system

- Inspection machine for the aeronautical industry

- Surface inspection system

- X-ray inspection system

- NDT inspection system

- Automatic inspection system

- Material inspection system

- 3D inspection system

- Aeronautical measuring arm

- Measuring arm

- 6-axis measuring arm

- 3D measuring arm

- Measuring arm with laser scanner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.