6-axis measuring arm XRHGantry CRfor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Number of axes

- 6-axis

- Other characteristics

- for the aerospace industry

Description

The inspection of heavy, big or oddly shaped parts demands for a versatile and scalable system. The XRHGantry CR is a roof-mounted turnkey solution designed to use Computed Radiography (CR) or film (RT) technology.

As technology is evolving VisiConsult suggests to go with real-time Digital Radiography (DR) through Flat Panel Detectors (FPD/DDA). Sometimes the application requirements or inspection process demands the usage of film or Computed Radiography (CR) plates. The XRHGantryCR was developed to speed up the rather slow inspection process with film and offers a flexible workflow.

Through the ultra-precise motors common inspection procedures can be automated into sequences. The tube can be tilted to allow an elliptical inspection of welds. The system can be placed inside an X-ray room or cabinet, while the X-ray source is scalable up to 450kV depending on the application. An additional part-manipulator or part-table is optional, while all axes are CNC programmable. Heavy parts can be moved in the inspection room on rails, lifting carts or even fork lifters. The dimensions of the XRHGantryCR can be modified to fit the existing inspection room. If there is no inspection room, VisiConsult can even deliver the system with a foldable X-ray cabinet.

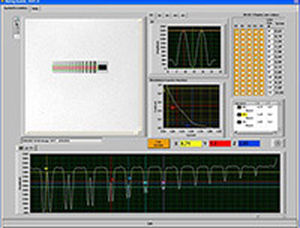

Clear digital radiography images including live enhancement

Designed for the inspection of big, heavy and complex parts

Automated inspection sequences and programmable CNC drives

Proven through many reference installations in the aerospace industry (NADCAP)

Designed for CR and RT inspection jobs

Customizable in terms of dimensions, layout and degrees of freedom

VIDEO

Catalogs

No catalogs are available for this product.

See all of Visiconsult GmbH ‘s catalogsRelated Searches

- Inspection system

- Inspection machine for the aeronautical industry

- Surface inspection system

- X-ray inspection system

- NDT inspection system

- Automatic inspection system

- Material inspection machine

- 3D inspection system

- Aeronautical measuring arm

- Measuring arm

- 6-axis measuring arm

- 3D measuring arm

- Measuring arm with laser scanner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.