6-axis measuring arm XRH RobotStarfor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Number of axes

- 6-axis

- Other characteristics

- for the aerospace industry

Description

In high volume industries like automotive the requirement for a hundred percent X-ray inspection creates a bottleneck in the production. The XRHRobotStar is a fully Automated Defect Recognition (ADR) capable robot-system that allows an ultra-fast in-line inspection.

The XRHRobotStar is an ultra-fast inspection system for all kinds of small to medium parts and can be equipped with up to 225kV. Successful reference systems for the inspection of aluminum casting parts exist in the automotive industry. The XRHRobotStar is the leading in-line inspection system on the market. By building a parallelized cluster solution consisting of several cabinets the throughput can be increased even more to scale with production extensions.

The basic functionality is that an (un)loading robot on the outside handles the incoming parts from the customer defined conveyor and distributes the inspected parts to the next processes, while on the inside a robot with a mounted C-Arm, including X-ray components, inspects the pre-programmed test-positions. The retrieved images are checked by the Xplus ADR for critical defector or other user defined criteria. In case of a mixed production the system can have different sequences for every part type. The parts will be recognized through a Data Matrix Code (DMC).

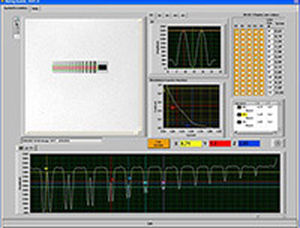

Clear digital radiography images including live enhancement

Part recognition through Data Matrix Codes (DMC) enable mixed inspection

Fully Automated Defect Recognition (ADR) of flaws and custom criteria

Designed for high volume in-line X-ray inspection

Free choice of X-ray components (tube, detector etc.) up to 225kV

Very short cycle time through high degree of parallel processes

VIDEO

Catalogs

No catalogs are available for this product.

See all of Visiconsult GmbH ‘s catalogsRelated Searches

- Inspection system

- Inspection machine for the aeronautical industry

- Surface inspection system

- X-ray inspection system

- NDT inspection system

- Automatic inspection system

- Material inspection machine

- 3D inspection system

- Aeronautical measuring arm

- Measuring arm

- 6-axis measuring arm

- 3D measuring arm

- Measuring arm with laser scanner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.