X-ray inspection machine XRH222automaticsurfacefor NDT

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray

- Other characteristics

- automatic

- Applications

- surface, for NDT

Description

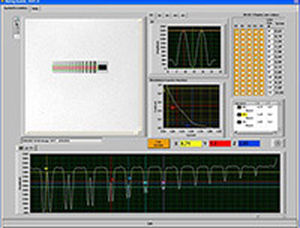

The XRH222 is one of the most versatile cabinets on the market and has dozens of successful installations. It can be used for all kinds of applications like real-time Digital Radioscopy (DR), fully automated ADR and even 3D-CT analysis. This leads to a completely new degree of freedom and flexibility in your inspection-process design!

Proven through many installations on the market the XRH222 with its robust industrial design is still manufactured in Germany under highest quality standards. The system is working with two separate manipulators: The 4 Axis part manipulator and a C-Arm can be controlled in a decoupled way. Due to the ultra-precise motors and the Xplus Handle all functionalities of the cabinet and image enhancement software can be easily automated by the operator without any programming knowledge.

The standard XRH222 supports 160kV, 225kV and micro-focus. Alternatively 320kV and 450kV are also available for thicker materials. In case of exceptionally big parts the XL version can even accommodate heights of up to 3250mm. To ease the part handling of such huge specimens VisiConsult developed the XRH222 TL, where parts can be lowered by crane. The S version can be chosen in case of space constraints.

Xplus: Clear digital radiography images including live enhancement

Native Computed Tomography (CT) functionality

Automated 24/7 inspection through Automatic Defect Recognition (ADR) and programmable CNC axes

Suitable for heavier and bigger parts in the XL version

Robust industrial design for a sustainable product with high reliability

Proven through many worldwide installations

VIDEO

Catalogs

Related Searches

- Inspection system

- Inspection machine for the aeronautical industry

- Surface inspection system

- X-ray inspection system

- NDT inspection system

- Automatic inspection system

- Material inspection machine

- 3D inspection system

- Aeronautical measuring arm

- Measuring arm

- 6-axis measuring arm

- 3D measuring arm

- Measuring arm with laser scanner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.