X-ray inspection machine XRH111automaticsurfacefor NDT

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray

- Other characteristics

- automatic

- Applications

- surface, for NDT

Description

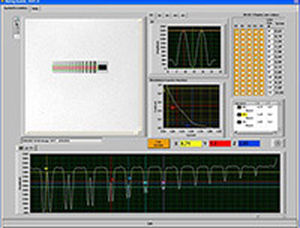

Universal X-ray cabinet to provide a maximum flexibility for inspection of small to medium sized parts. The XRH111 combines a compact footprint and minimum-cost layout with high-end features like Computed Tomography (CT) and Automatic Defect Recognition (ADR). This leads to an efficient and scalable X-ray inspection system for a very economical price.

Due to its flexibility the XRH111 is the perfect universal inspection system. Switching between Automatic Defect Recognition (ADR), 3D-CT laboratory inspection or manual testing is done effortlessly without any downtimes. This leads to an increased system utilization and saves investment costs for multiple systems. The operator just loads a defined parameter set and the system is ready for the new task. In day to day business this simplicity and efficiency is the key to success. In case of purely visual inspection a budget alternative is the XRH111 ECO.

The XRH111 is a X-ray cabinet to test all kinds of parts up to a diameter of 400mm and a height of 600 mm that do not exceed 25kg. Depending on the job-requirements the system is available with 160kV, 225kV or micro-focus tubes. The cabinet has a footprint of 1650 mm x 1450 mm x 2300 mm and is certified by the German TÜV, which ensures absolute safety, no X-ray leakage, fulfillment of all standards and an ergonomic operator position.

Clear digital radiography images including live enhancement

Native Computed Tomography (CT) functionality

Automated 24/7 inspection through Automatic Defect Recognition (ADR) and programmable CNC drives

Designed for small to medium sized parts like castings

Minimum changeover times between different applications

VIDEO

Related Searches

- Inspection system

- Inspection machine for the aeronautical industry

- Surface inspection system

- X-ray inspection system

- NDT inspection system

- Automatic inspection system

- Material inspection machine

- 3D inspection system

- Aeronautical measuring arm

- Measuring arm

- 6-axis measuring arm

- 3D measuring arm

- Measuring arm with laser scanner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.