- Production - Materials - Metrology

- Materials - Semi-finished products

- Epoxy resin

- Toray Advanced Composites

Epoxy resin E732for composites

Add to favorites

Compare this product

Characteristics

- Other characteristics

- epoxy

- Other characteristics

- for composites

Description

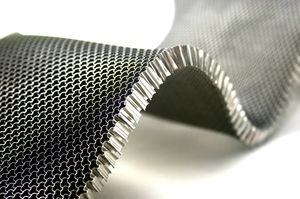

E732 is a snap cure toughened epoxy resin matrix optimized for press curing (compression molding) prepreg applications. With a cure time of 4 minutes at 160°C (320°F), an onset Tg of 170°C (338°F) is achieved. At this higher temperature, medium to high production rates can be accomplished, with customers’ able to produce beyond 50,000 parts per year.

Toray E732 is a versatile matrix with a range of processing options allowing a variety of automotive and industrial applications to be realized.

Product benefits/features

Hot-in hot-out press processing

Good surface finish and aesthetics

Controlled resin flow for ease of processing

Full Tg of 170°C (338°F) reached in 4 minutes at 160°C (320°F)

Market segments

Sport & Recreation

Automotive

Energy

Consumer Electronics

Industrial

eVTOL / Urban Air Mobility

Details

Product category - Thermoset Prepreg

Processing - Out of Autoclave / Vacuum bag

Press forming

Autoclave

Resin type - Epoxy

Tg (Dry, onset) - 170 °C / 338 °F

Cure temperature (Optimal) - 160 °C / 320 °F

Cure temperature (Lowest) - 120 °C / 248 °F

Cure temperature (Highest) - 160 °C / 320 °F

Out life - 21 days

Catalogs

Toray E732

6 Pages

Related Searches

- Aeronautic composite

- Aeronautic honeycomb

- Composite

- Resin composite

- Composite for the aerospace industry

- Aeronautic prepreg

- Prepreg

- Resin prepreg

- Thermoplastic resin composite

- Carbon fiber composite

- Aluminum honeycomb

- Composite resin

- Resin

- Epoxy resin prepreg

- Epoxy resin

- Fiberglass composite

- Fire-resistant honeycomb

- Honeycomb for the aerospace industry

- Laminate composite

- Thermoplastic resin prepreg

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.