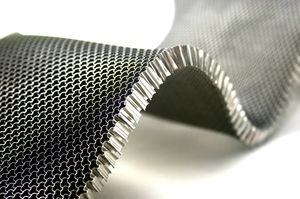

Plastic honeycomb Nomex®for the aerospace industryfire-resistant

Add to favorites

Compare this product

Characteristics

- Material

- plastic

- Applications

- for the aerospace industry, fire-resistant

- Length

1,250 mm

(49 in)- Width

2,500 mm

(98 in)

Description

ANA aerospace grade Nomex® honeycomb core is manufactured from Nomex® paper sheets and is coated and bonded together with a phenolic resin.

Designed to offer users and designers high strength-to-weight properties at relatively low cost, Nomex® honeycomb is particularly suitable as a core material for production of sandwich structures requiring significant FST performance and using high performance fiber reinforced composites as the facing material.

Typical applications include:

> Sandwich panel applications

> Aircraft flooring – varying densities depending on level of duty

> Aircraft interiors – ranging from sidewalls, galleys, and ceilings, including commercial aerospace, business, and VIP interiors

> Cargo lining

> Aircraft leading and trailing edges

> Helicopter rotor blades

> Fuselage components

Product benefits/features

High strength-to-weight ratio

Easily formed to shape

Excellent fire-resistant and self-extinguishing properties to FAR 25.583

Corrosion resistance against water, oil, and fuel

High temperature capabilities; service temperature up to 180°C (356°F)

Good dielectric properties

Cut to customer thickness specification

Catalogs

Related Searches

- Aeronautic composite

- Aeronautic honeycomb

- Composite

- Resin composite

- Composite for the aerospace industry

- Aeronautic prepreg

- Prepreg

- Resin prepreg

- Thermoplastic resin composite

- Carbon fiber composite

- Aluminum honeycomb

- Composite resin

- Resin

- Epoxy resin prepreg

- Epoxy resin

- Fiberglass composite

- Fire-resistant honeycomb

- Honeycomb for the aerospace industry

- Laminate composite

- Thermoplastic resin prepreg

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.