- Software - Simulation

- Software

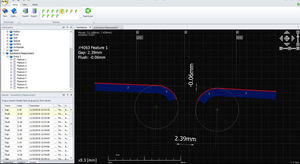

- Measurement software

- Third Dimension

Measurement software LINKdata managementdata collectionfile import/export

Add to favorites

Compare this product

Characteristics

- Function

- data management, data collection, file import/export, control, data analysis, measurement, spark optical emission, CAD data analysis, process

- Applications

- for aeronautics, for MRO

- Type

- real-time, 2D

Description

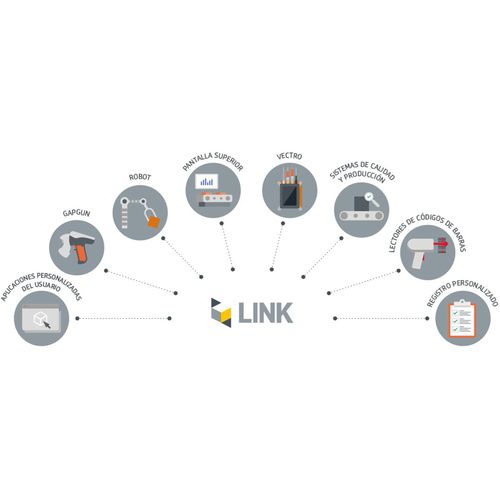

Integrate GapGun and Vectro measurement tools into your existing production systems using Link

01

INTEGRATION WITH A MEASUREMENT DATABASE

Measurement requirements including tools, nominals and tolerances, and measurement results are stored in the customer's data systems. The operator uses a custom Link application with a simple UI which automatically transfers measurement requirements and results between the database and the GapGun.

02

REAL-TIME RESULTS CAPTURE AND DISPLAY

GapGuns are integrated into an existing system for capturing and displaying real-time production data. The operator works with the GapGun as normal. Behind the scenes a custom Link application relays results from the GapGUn to the customer's data system.

03

INTEGRATION WITH A ROBOT

An inspection cell uses a Vetro in a fixed position with a robot moving the parts to be measured into place. The machine is operated through a custom Link application which controls and synchronises the robot and Vectro.

04

BARCODE DRIVEN MEASUREMENT INTEGRATION

The check plan is selected by scanning a barcode and measurement results are placed in a customised output file for import into the customer's quality control system. Behind the scenes a custom Link application determines which works order is requires, sends it to the GapGun, retrieves the results and generates the output file.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.