- Production - Materials - Metrology

- Production machine

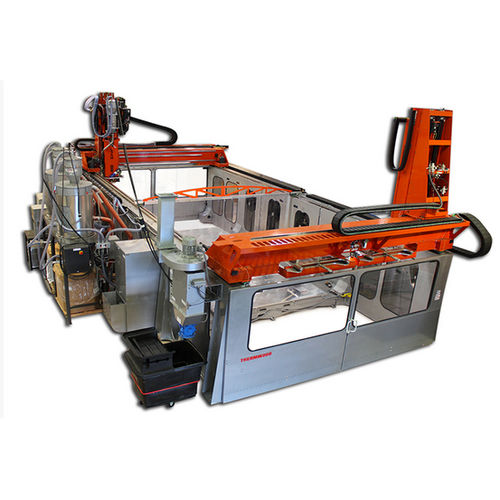

- Composite router

- THERMWOOD CORPORATION

- Products

- Catalogs

- News & Trends

- Exhibitions

Composite router LSAM 5-axis or moreCNCfor aeronautics

Add to favorites

Compare this product

Characteristics

- Dispensed product

- for composites

- Number of axes

- 5-axis or more

- Other characteristics

- CNC, for aeronautics

Description

LSAM ® (pronounced L-Sam) is Thermwood’s name for its line of Large Scale Additive Manufacturing machines used to produce large to very large sized components from reinforced thermoplastic composite materials. Although suitable for producing a wide variety of components, Thermwood is focusing on producing industrial tooling, masters, patterns, molds and production fixtures for a variety of industries including aerospace, automotive, foundry and boating. Thermwood’s LSAM ® machines use a two-step, near-net-shape production process. The part is first 3D printed layer by layer, to slightly larger than the final size, then it is trimmed to its exact final net size and shape using a CNC router. The process operates in free space and does not require molds or tooling. LSAM ® machines perform both printing and trimming on the same machine using two gantries, one for printing and one for trimming.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.