- Products

- Catalogs

- News & Trends

- Exhibitions

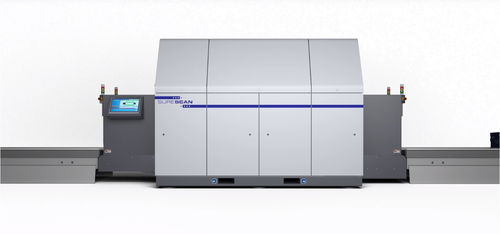

Baggage scanner x1000for explosives detectionfor airportX-ray

Add to favorites

Compare this product

Characteristics

- Applications

- baggage, for explosives detection

- Sector

- for airport

- Type

- X-ray

- Other characteristics

- with conveyor, 3D, 2D

Description

Flexible Throughput

Upgradeable belt speed, large rectangular tunnel throughput

Multi-Energy Photon Counting

Multi-energy vs. dual energy, future proof design for evolving threats and standards

Intelligent Platform

With more precise measurements and multiple energies, it already provides the data for a algorithm development in the future

Lower Life Cycle Cost of Ownership

Less power, less repair & Maintenance

Stationary Gantry

Higher reliability, no moving parts, self calibration

CT Geometry -

Fixed sources; no rotating gantry; minimal moving parts (conveyor belt and fans only)

Tunnel Dimensions (W x H) - 1000 mm x 800 mm

Maximum Object Size (W x H x L) -

1000 mm x 800 mm x 2510 mm; full rectangular tunnel the length of the scanner (no neckdown)

Dimensions & Weight (W x H x L) -

2210 mm x 2274 mm x 4843 mm; 5942 kg (height customizable up to 2655 mm based on pedestal size)

Conveyor Height -

457 mm (height customizable up to 838 mm based on pedestal size)

Belt Speed - .5 m/s

Operation Environment -

Scanner: 0°C up to 40°C; 0% to 95% RH, non-condensing, air-cooled scanner, no air conditioning required CT/Multiplexer Rack: 0°C to 40°C; 0% to 95% RH, non-condensing.

Power Supply Requirements -

Scanner: 400/480/575 VAC +/-5%, 3-phase, 50/60 Hz, 15 amps (typical loads) at 480 VAC CT/Multiplexer Rack: 208 VAC, 50/60 Hz; 3 drops (one 15 amps, two 10 amps – typical loads)

Power Consumption -

Scanner: 7.5 kW typical. 50% less power than rotating gantry.

21 CFR part 1020.40 Cabinet X-ray Systems and Council Directive 2013/59/Euratom Validation to country specific limits performed in-house and on site

X-ray Voltage - 160kV

Electrical Safety -

Intertek CE Mark Electrical Safety

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.