3D imaging crack detector EddyCus® CF inline ISOfor aeronautics

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Technology

- 3D imaging

- Applications

- for aeronautics

Description

Online process monitoring allows immediate feedback and closed-loop manufacturing of carbon fiber materials. The CF inline ISO provides isotropy data for the continuous roll-to-roll process of recycled carbon fiber, UD-tapes or similar configurations. The solution offers real-time data across the entire width of the web at a competitive price.

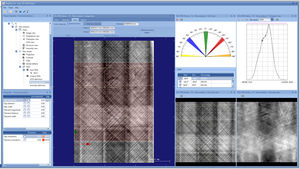

The EddyCus® CF inline ISO is an inline solution for recording the fiber orientation and fiber areal weight of each fiber layer of an entire stack. This allows you to react immediately and realign the layers as soon as deviations from the target are detected. The monitoring system can monitor the fiber layer at various angles e.g. 0°, 90°, -45° or 45° at one or more lanes at a single point. It compares the polar plot of a reference with the polar plot of a currently produced ply, checking the difference in the angles of the inflection points and also the length of the plots. This gives you the information you need to determine the quality of the product and monitor the production process – the orientation of the layers and the fiber area weight of each layer. The picture on the right shows an example of a possible visualization of a two-layer stack. The black line shows the expected values determined by a reference and the red line corresponds to the values of the measured stain.

How can the polar diagram shown on the right be interpreted?

The orientation of the fibers corresponds quite closely to the expected value. This can be seen from the fact that the inflection points of the reference and the examined material have the same angle.

The fiber area weight deviates significantly from the desired result.

Catalogs

No catalogs are available for this product.

See all of SURAGUS GMBH‘s catalogsRelated Searches

- Laser scanner

- Aeronautic laser scanner

- Non-contact laser scanner

- Aeronautic thickness gauge

- Thickness gauge

- Coating thickness gauge

- 3-axis laser scanner

- NDT thickness gauge

- Contact laser scanner

- Eddy current thickness gauge

- Digital display thickness gauge

- Glass thickness gauge

- Aeronautic crack detector

- Crack detector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.