- Products

- Catalogs

- News & Trends

- Exhibitions

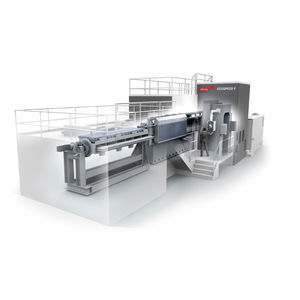

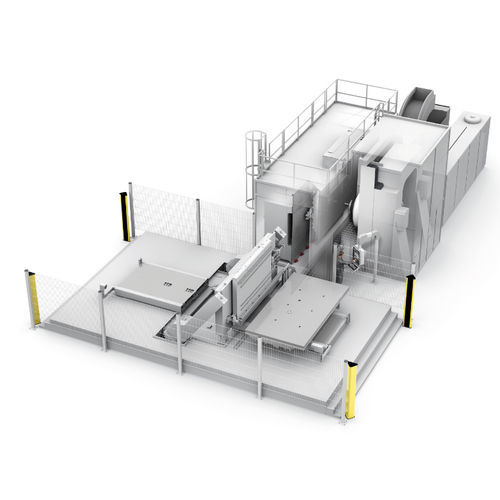

5-axis machining center ECOSPEED F 2035horizontalfor the aerospace industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Applications

- for the aerospace industry

- Rotational speed

30,000 rpm

(188,496 rad.min-1)- X travel

3,500 mm

(137.8 in)- Y travel

2,000 mm

(78.74 in)- Z travel

370 mm, 670 mm

(14.57 in, 26.38 in)

Description

Scharmann has developed the ECOSPEED F for high-speed machining of mediumsized aluminium structural components. The horizontal spindle arrangement, the vertical pallet arrangement and the Sprint Z3 parallel kinematic machining head, which delivers high travel speeds (50 m/min) and accelerations (9.81 m/s²), all come from the successful ECOSPEED.

What sets the F version apart from the standard ECOSPEED is that the machine column is stationary. The pallet travels in the X direction on the vertically arranged table group. The ECOSPEED F is equipped with a rotating double pallet station, located parallel to the X-axis, which enables component loading and unloading during the machining cycle.

Parallel kinematic machining head - Sprint Z3

Sprint Z3 and the parallel kinematic concept: Three parallel linear axis drives are mounted radially equispaced in a barrel-shaped headstock. The spindle platform is connected to each drive by means of rigid levers with a simple pivot at one end, and a ball joint at the other end. A high performance motor spindle is mounted to the spindle platform.

Highest availability

Due to proven components the machine offers much higher availability as traditional machine concepts.

Acceleration in all axes

High acceleration / deceleration of 1 G in all axes.

Highly efficient chip removal and surface quality

The machine concept is valid as the world's most productive solution for the machining of aluminum structural parts at highest surface finish quality.

Head attachments

Automatic change of head attachments like angular milling heads.

VIDEO

Related Searches

- Machining machine

- Aeronautic machining center

- 5-axis machining center

- CNC machining center

- Aeronautic milling machine

- Milling machine

- CNC milling machine

- Multi-axis milling machine

- Horizontal machining center

- Vertical machining center

- Machining center for the aerospace industry

- Aeronautic grinding machine

- Grinding machine

- Gantry machining center

- Machining center with swiveling spindle

- 4-axis machining center

- Horizontal milling machine

- Turning center

- Aeronautic lathe

- CNC lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.