- Products

- Catalogs

- News & Trends

- Exhibitions

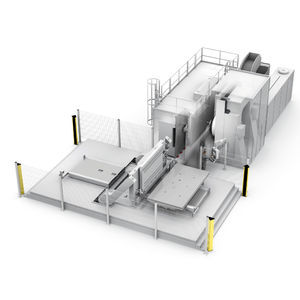

5-axis machining center ECOSPEED F 1540horizontalfor the aerospace industrywith moving table

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Applications

- for the aerospace industry

- Other characteristics

- with moving table

- Rotational speed

30,000 rpm

(188,496 rad.min-1)- X travel

4,300 mm

(169.29 in)- Y travel

1,600 mm

(62.99 in)- Z travel

370 mm, 670 mm

(14.57 in, 26.38 in)

Description

Ecospeed is the synonym for the most economic method of machining complex aluminium structural components in the aerospace industry. Based around its’ unique parallel kinematics Sprint Z3 machining head, Ecospeed represents by far the most productive solution for the high performance cutting of monolithic aluminium aerostructures. The Ecospeed family has been continuously developed to meet market demands. New challenges imposed by the market are implemented within a team framework, by maintaining intensive contact with end users.

Yet another recent customer-driven requirement placed on the Starrag Technology GmbH management board was to supply an optimized economic Ecospeed variant for machining long and narrow structural components at high cutting rates and using complex 5-axis geometries with 5-side access to the work piece.

Parallel kinematic machining head - Sprint Z3

Sprint Z3 and the parallel kinematic concept: Three parallel linear axis drives are mounted radially equispaced in a barrel-shaped headstock. The spindle platform is connected to each drive by means of rigid levers with a simple pivot at one end, and a ball joint at the other end. A high performance motor spindle is mounted to the spindle platform.

Highest availability

Due to proven components the machine offers much higher availability as traditional machine concepts.

Acceleration in all axes

High acceleration / deceleration of 1 G in all axes.

Highly efficient chip removal and surface quality

The machine concept is valid as the world's most productive solution for the machining of aluminum structural parts at highest surface finish quality.

VIDEO

Related Searches

- Machining machine

- Aeronautic machining center

- 5-axis machining center

- CNC machining center

- Aeronautic milling machine

- Milling machine

- CNC milling machine

- Multi-axis milling machine

- Horizontal machining center

- Vertical machining center

- Machining center for the aerospace industry

- Aeronautic grinding machine

- Grinding machine

- Gantry machining center

- Machining center with swiveling spindle

- 4-axis machining center

- Horizontal milling machine

- Turning center

- Aeronautic lathe

- CNC lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.