- Products

- Catalogs

- News & Trends

- Exhibitions

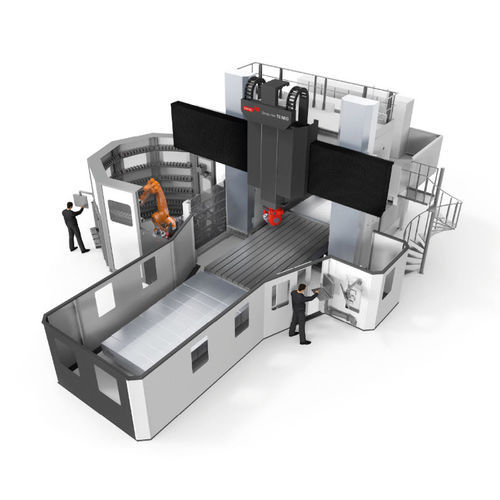

6-axis machining center TSverticalfor aeronauticsCNC

Add to favorites

Compare this product

Characteristics

- Number of axes

- 6-axis

- Spindle orientation

- vertical

- Applications

- for aeronautics

- Other characteristics

- CNC, gantry

- Rotational speed

Min.: 4,000 rpm

(25,133 rad.min-1)Max.: 6,000 rpm

(37,699 rad.min-1)- X travel

Min.: 3,000 mm

(118.11 in)Max.: 6,000 mm

(236.22 in)- Y travel

Min.: 3,000 mm

(118.11 in)Max.: 4,000 mm

(157.48 in)- Z travel

Min.: 1,500 mm

(59.06 in)Max.: 2,500 mm

(98.43 in)

Description

Flexibility, efficiency and precision play a very important role for machine manufacturers and tool builders, especially when dealing with large components. These three requirements led to the development of the gantry machining centre TFS NEO with a fixed and movable crossbeam, whereby the customer chooses the table designs, controls and milling units suitable for them on a modular basis. The TFS NEO features a new milling unit and a modified C-axis (±400°) which, thanks to its enormous flexibility, can be used for efficient production of highly precise machine parts.

The large number of automatically changeable milling heads increases the machine's flexibility within its scope of application.

The TFS also allows automatic tool or spindle changing and tool or workpiece measurement.

Milling unit D40

Milling unit D40 with integrated C-axis and up to 40 kW power (S1) positioned- and clamped P-Version continous controlled C-Version.

Tool holders

As tool interfaces it offers SK 50, HSK-A100 and HSK A63.

Tool measuring / component probing

It offers automatic tool measuring and part probing.

Automatic tool changer

The series offers different tool magazine solutions likechain type magazines with up to 80 pockets or robot supported tool magazines with up to 320 pockets.

Master-/Slave drive

Double pinion, electronically preloaded by two feed drives

High stiffness

High position accuracy

Easy maintenance by reduced numbers of drive elements.

Fork-type milling head

Self manufactured fork type head for 3+2 axis machining in P-Version or five axis machining in C-version.

Control options

The series offers the Heidenhain iTNC 530 or Siemens Sinumerik 840 D control.

Related Searches

- Machining machine

- Aeronautic machining center

- 5-axis machining center

- CNC machining center

- Aeronautic milling machine

- Milling machine

- CNC milling machine

- Multi-axis milling machine

- Horizontal machining center

- Vertical machining center

- Machining center for the aerospace industry

- Aeronautic grinding machine

- Grinding machine

- Gantry machining center

- Machining center with swiveling spindle

- 4-axis machining center

- Horizontal milling machine

- Turning center

- Aeronautic lathe

- CNC lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.