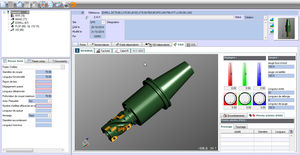

- Software - Simulation

- Software

- Interoperability software

- SPRING Technologies

Management software MonitorreportingplanningERP

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- management, reporting, planning, ERP, quality, interoperability, monitoring, automation

- Applications

- for aeronautics

- Type

- real-time

Description

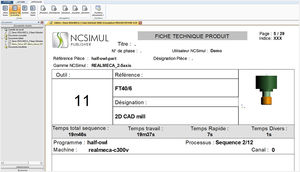

Real-time machine status monitoring software

NCSIMUL Monitor returns machine status, either manually from the NC console or automatically. It delivers native support for OPC, the international interoperability standard for industrial automation.

This means that a machine's status can be reported in real time with details of output, failures, downtime, setups, etc. This data can be used to generate activity reports in table or graph form to enable specific situations to be analyzed and more efficient production planning. Status reporting also enables the execution of quality scenarios and more sophisticated supervision processes. Interfaced with an ERP or Production Management package providing links to work/planned orders, the module provides feedback on productivity rates (OEE*, ORR*, EIRR*) in a single click.

CHALLENGES

Errors caused by manual actions appear in the NC program

You spend too much time transferring your NC programs to your CNC machines

Changes you make to your programs are not traceable

You use multiple systems to transfer your CNC programs

The NC program uploaded was not the right version

BENEFITS

Machine status monitoring, in real time, with details of outputs, failures, downtime, setup, etc.

Increase machine productivity

Ease of use

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.