- Software - Simulation

- Software

- Process software

- SPRING Technologies

CAM software 4 manufacturingprogrammingcutting

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- CAM, manufacturing, programming, cutting, process, machining

- Applications

- for aeronautics

- Other characteristics

- NX, Creo

Description

Streamlined, bi-directional & seamless End-to-End machining process

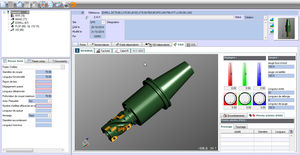

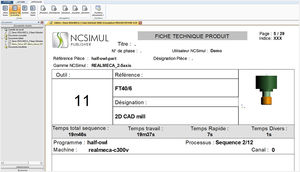

NCSIMUL 4CAM is enriching the existing CAM process to simplify CNC programming. It provides unparalleled flexibility on the shopfloor. It allows to change, in one click, the target machine, without any CAM reprogramming.

From the main CAM (e.g., CAM solutions from Hexagon such as ESPRIT TNG, EDGECAM, SURFCAM, VISI Machining and ALPHACAM or other CAM solutions such as CATIA CAM, NX CAM, Creo CAM, Mastercam, hyperMILL, POWERMILL, TOPSOLID CAM etc.) or existing CNC programs (G-code format), NCSIMUL 4CAM generates directly (without external post-processor), CNC native programs, verified and optimized taking into account the physical means of the workshop (tools, cutting conditions, kinematics, machine controllers ...)

CHALLENGES

Re-write and re-work former CNC programs for new machines without reprogramming

Switch part production between machines at the last minute

Re-engineer some of your toolpaths and need to reprogram

Develop and maintain specific post processors to generate G-code programs

Capitalize changes to your G-code program

BENEFITS

Generate automatically new CNC machine programs from a formally created CNC toolpath

Switch your part machining between the different CNC's, on-the-fly, without reprogramming

Reuse existing APT or G-code files with just a copy/paste click, to optimize the manufacturing process

Eliminate external postprocessors thanks to the integrated CNC processor

Connections between machine sequences are automatically calculated in an optimal way

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.