- Software - Simulation

- Software

- Machining software

- SPRING Technologies

Quality software Optitoolanalysissimulationcutting

Add to favorites

Compare this product

Characteristics

- Function

- quality, analysis, simulation, cutting, machining

- Applications

- for aeronautics

Description

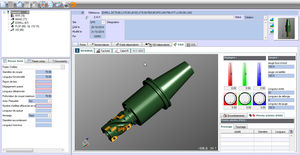

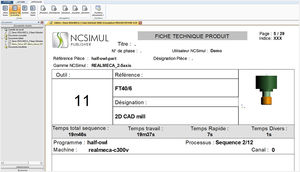

NCSIMUL Optitool analyzes cutting conditions, dramatically reduces “air cutting,” optimizes feed rates, and allows users to create better cutting strategies. The sum benefits are a reduction in the production cycle times, enhancement of cutting operations, and fast development of new G code optimized files for future applications.

This NCSIMUL Machine module allows you to optimize the tool lengths, air cutting and cutting conditions of your NC programs (from 3 to 5 axis simulation software).

Reduce the operating cycle of your programs

Enhance the quality of your machining operations

Tool length optimization (NCSIMUL Machine standard feature)

Reduction of bending phenomena as well as collision risks with the tool support (attachment + extensions)

Suppression of the collisions with the tool support as well as reduction of the toolbeding

Air cutting optimization

Thanks to NCSIMUL Optitool, the NCSIMUL Machine user can define its own approach and retract motion parameters in order to minimize the air cutting and maximize the use of rapid motion (or working feedrate with high speed).

Analysis of cutting conditions for each toolpath section in a block by multi-criteria search

NCSIMUL Optitool features a multi-criteria search function which allows users to analize one or a set of NC programs for one or several tools in accordance with their cutting parameters. Without requiring any modification in the program, NCSIMUL Optitool is able to find the tool trajectory sections (can be set up in function of the tool diameter) that do not match the cutting conditions defined by users.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.