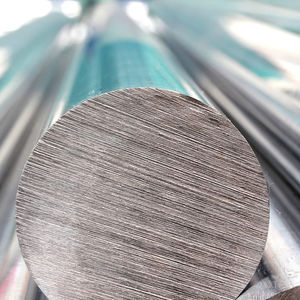

Tube alloy steel 4130 for the aerospace industry

Add to favorites

Compare this product

Characteristics

- Form

- tube

- Other characteristics

- for the aerospace industry

- Mechanical resistance

689 MPa, 862 MPa

- Typical elongation

12 %

Description

4130 steel tube is a general-purpose steel product that has been a mainstay of the aerospace sector for many years. The alloy is often referred to as 'chromoly' or 'chrome moly' due to chromium and molybdenum content. 4130 offers good fabricability, is malleable, and weldable, although welding to other carbon steels is not recommended. Heat treatments at the pre and post-weld stage are advisable to avoid cold cracking. The alloy provides good abrasion and impact resistance.

Performance

4130 offers greater hardness and strength than standard carbons steel grades and provides a good strength to weight ratio. As the product is stronger than carbon steel, tubing with a thinner wall can be used, which reduces weight. The alloy benefits from widespread use, including bicycle frames, roll cages and aerostructures.

Metallurgical Support

Our UKAS Accredited Testing Laboratory is unique to the stockholding sector and we offer our customers a range of testing services combined with comprehensive metallurgical support.

Stock Availability

(including normalised, cold drawn and hot finished conditions). We also offer an in-house tube cutting service where we process your steel tubes to exact lengths.

Applications

Bicycle frames

Tie rods

Drill collars

Machine shafts

Product Benefits

Greater hardness than standard carbon steels

High mechanical strength

Good weldability

Good fabrication

Catalogs

Material

1 Pages

Related Searches

- Aeronautical stainless steel

- Stainless steel

- Alloy steel

- Aeronautical alloy steel

- Titanium alloy

- Aeronautical titanium alloy

- Aluminum alloy

- Aeronautical aluminum alloy

- Steel alloy for the aerospace industry

- Stainless steel for the aerospace industry

- Aerospace titanium alloy

- Nickel alloy

- Nickel alloy for the aerospace industry

- Aluminum for the aerospace industry

- Titanium alloy rod

- Bronze

- Aeronautical copper alloy

- Rod nickel alloy

- Rod stainless steel

- Steel alloy rod

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.