- Production - Materials - Metrology

- Materials - Semi-finished products

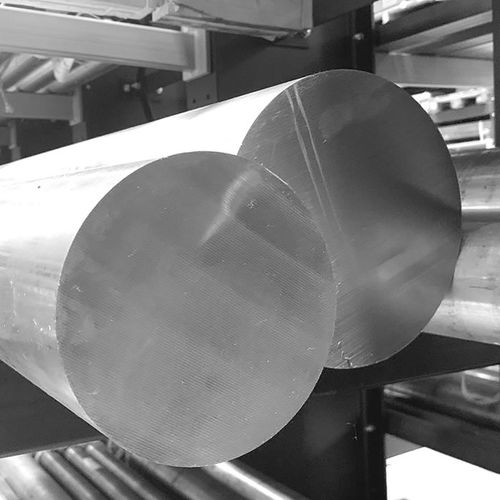

- Titanium rod

- SMITHS ADVANCED METALS

Titanium alloy rod 6242Ti-6Al-4Vgrade 5aerospace

Add to favorites

Compare this product

Characteristics

- Form

- rod

- Type

- Ti-6Al-4V, grade 5

- Other characteristics

- aerospace, AMS 4975

- Mechanical resistance

896 MPa

- Elasticity

827 MPa

- Typical elongation

10 %

Description

6-2-4-2 (6AL-2SN-4ZR-2MO) titanium alloy combines outstanding mechanical strength and stability. Creep resistance is also impressive, performing at temperatures as high as 538° C (1000° F). Machining and forging characteristics for the alloy are very similar to Grade 5 titanium (Ti-6Al-4V). These performance characteristics allow customers to create components that work effectively at much higher working temperatures. We stock 6-2-4-2 titanium bars in the annealed condition and in various sizes to suit your requirements.

For High Performance Applications

6242 titanium alloy finds use in high-performance applications throughout industry. The alloy is lightweight with excellent mechanical strength, which provides designers and engineers with options, particularly in market sectors such as motorsport and aerospace. Strength to weight ratios are critical in these markets, and both titanium and aluminium feature heavily in the manufacture of high-performance components and structures.

Commercial Applications

6242 titanium bar is a high-performance engineering alloy and finds use in engineering applications, including motorsport components, gas turbine engines, impellers and aerospace structural parts.

Grades / Specifications

AMS4976

MSRR8662

3.7144

6Al-2Sn-4Zr-2Mo

UNS R54620

Applications

Gas turbine engines

Aerospace structural components

Motorsport components

Impellers & turbines

Product Benefits

Outstanding mechanical strength

Impressive creep resistance

Good machinability

High toughness

Catalogs

No catalogs are available for this product.

See all of SMITHS ADVANCED METALS‘s catalogsRelated Searches

- Aeronautical stainless steel

- Stainless steel

- Alloy steel

- Aeronautical alloy steel

- Titanium alloy

- Aeronautical titanium alloy

- Aluminum alloy

- Aeronautical aluminum alloy

- Steel alloy for the aerospace industry

- Stainless steel for the aerospace industry

- Aerospace titanium alloy

- Nickel alloy

- Nickel alloy for the aerospace industry

- Aluminum for the aerospace industry

- Titanium alloy rod

- Bronze

- Aeronautical copper alloy

- Rod nickel alloy

- Rod stainless steel

- Steel alloy rod

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.