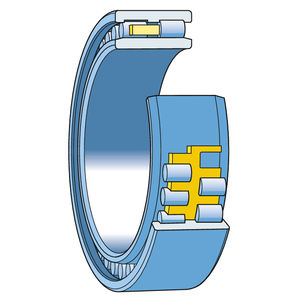

Cylindrical roller bearing single-rowhigh-speedwith cage

Add to favorites

Compare this product

Characteristics

- Rolling element

- cylindrical roller

- Configuration

- single-row

- Other characteristics

- high-speed, with cage, low-friction

Description

SKF single row cylindrical roller bearings are available in many designs, series and sizes. The major design differences between the bearings presented in this section are in:

the cage design and material

the configuration of the inner and outer ring flanges

Low friction (Roller end / flange contact area)

The open flange design (fig. 2), together with the roller end design and surface finish, promote lubricant film formation resulting in lower friction and higher axial load carrying capacity.

Long service life

The logarithmic roller profile reduces edge stresses at the roller/raceway contact (fig. 3) and sensitivity to misalignment and shaft deflection.

Enhanced operational reliability

The surface finish on the contact surfaces of the rollers and raceways supports the formation of a hydrodynamic lubricant film.

Separable and interchangeable

The separable components of SKF cylindrical roller bearings are interchangeable (fig. 4). This facilitates mounting and dismounting, as well as maintenance inspections.

High speed capability

The cage designs are suitable for high speeds, rapid accelerations and peak loads

Catalogs

No catalogs are available for this product.

See all of SKF AEROSPACE‘s catalogsRelated Searches

- Bearing

- Ball bearing bearing

- Steel bearing

- Roller bearing

- Corrosion-resistant bearing

- Radial bearing

- Precision bearing

- Double-row bearing

- Single-row bearing

- Angular-contact bearing

- Heavy load bearing

- Deep groove bearing

- Cage assembly bearing

- Axial bearing

- Cylindrical roller bearing

- Self-aligning bearing

- Sealed bearing

- High-speed bearing

- Stainless steel bearing

- Needle roller bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.