- Production - Materials - Metrology

- Surface treatment

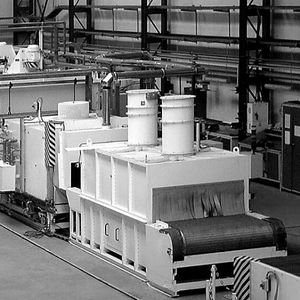

- Electric furnace

- SECO/WARWICK DO BRASIL LTDA

Electric furnace cabinetfor the aerospace industrycontinuous

Add to favorites

Compare this product

Characteristics

- Heat source

- electric

- Configuration

- cabinet

- Other characteristics

- for the aerospace industry, continuous

Description

SECO/WARWICK is one of the world’s most experienced and innovative brazing furnace manufacturers with over 300 controlled atmosphere brazing (CAB) systems installed worldwide. Our commitment to quality products begins in our brazing center, application engineering and continues through the complete installation of your system, including aftermarket support.

Controlled atmosphere brazing (CAB) of aluminum using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers. Since entering this field in 1984, SECO/WARWICK has led the development of advanced technology in the aluminum brazing process. Capitalizing on our many decades of furnace design experience, SECO/WARWICK has driven innovations such as:

/ Improved muffle design

/ Convection heating technology

/ High atmosphere quality solution

/ Vacuum purging system for semi-continuous and batch furnaces

/ ACCUBRAZE® PC/PLC controls

/ Customized heating systems: electrical or gas

/ Energy saving designs

Our continuous CAB furnaces, as described below, use a variable speed drive and a stainless-steel mesh belt to move products. The controlled atmosphere brazing (CAB) process heats a product to brazing temperatures while maintaining uniform temperatures within the product in an oxygen-free nitrogen atmosphere. During furnace brazing, a brazing sheet of aluminum/silicon alloy plate (cladding) is heated to a liquid state and flows to form aluminum joints or fillets. Al-Si phase diagram giving reference to the different alloys used for CAB brazing with temperatures of the liquid phase for each.

Controlled Atmosphere Brazing Process

Catalogs

No catalogs are available for this product.

See all of SECO/WARWICK DO BRASIL LTDA‘s catalogsOther SECO/WARWICK DO BRASIL LTDA products

Aluminum Furnaces for Heat Treatment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.