- Production - Materials - Metrology

- Surface treatment

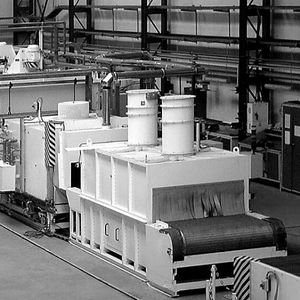

- Electric furnace

- SECO/WARWICK DO BRASIL LTDA

Electric furnace cabinetfor the aerospace industryannealing

Add to favorites

Compare this product

Characteristics

- Heat source

- electric

- Configuration

- cabinet

- Other characteristics

- for the aerospace industry, annealing

Description

SECO/WARWICK offer industrial furnaces equipped with advanced technology to reduce cycle times, conserve energy and improve cooling rates. Our five basic product groups include coil/foil annealing, solution heat treatment & aging, log/ingot homogenizing and melting/holding furnaces. Each system includes control and material handling packages designed to provide optimum performance in each unique production environment.

With over 50 years of experience working with the aluminum industry, we see your production needs and offer equipment with exceptional quality and value.

/ Production flexibility

Because of its multi-zone design, vertical airflow furnace technology is inherently flexible. The furnace can now process batches of different alloys and diameters without leaving empty saddles.

/ Automatic handling

The furnace’s operation is completely automated by the control system. No user interaction is required during normal operation when a stoppage occurs or when the furnace needs to be restarted after a stoppage. Stoppages and restarts usually involve significant risks of product damage. Because the process is completely automated, all variations inherent in human control of such a process are eliminated and the consistency of the operation is improved.

/ Product traceability

The PLC captures detailed historical data (position, temperature, degree of transformation, residence time) for each billet. The system also makes reports on single billets and batches of billet available based on the captured data. The data and reports can be used to improve the process and to respond to customer questions.

Catalogs

No catalogs are available for this product.

See all of SECO/WARWICK DO BRASIL LTDA‘s catalogsOther SECO/WARWICK DO BRASIL LTDA products

Aluminum Furnaces for Heat Treatment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.