- Production - Materials - Metrology

- Surface treatment

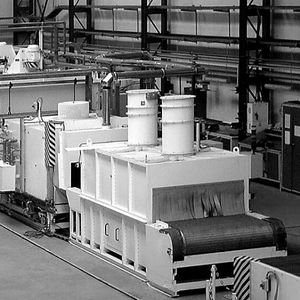

- Electric furnace

- SECO/WARWICK DO BRASIL LTDA

Electric furnace VERTIQUENCHcar bottomfor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Heat source

- electric

- Configuration

- car bottom

- Other characteristics

- for the aerospace industry

Description

SECO/WARWICK is a full-service integrator of aluminum processing technologies serving the worldwide aluminum industry with efficient lines that perform with exceptional temperature uniformity and custom designed charging techniques to fit the most demanding applications. The company’s furnaces provide the world’s best implementation of heat treatment processes, top quality of processed products and support for heat treatment equipment and processes. Significant technical improvements have been implemented resulting in numerous drop bottom furnaces installation. As a result, this equipment has become a top product for SECO/WARWICK so, new brand name has been developed, VertiQuench®.

VertiQuench® Drop Bottom Furnaces provide an affordable solution for demanding automotive and aerospace applications in aluminum solution heat treatment and aging. This innovative NADCAP compliant technology enables very fast and full load immersion, as short as 5 seconds.

As the VertiQuench® name implies, the process provides vertical quenching. The heat-treated material is dropped into water or polymer quenching tanks located directly under the furnace.

VertiQuench® provides solution heat treatment followed by quenching and artificial aging for precipitation hardening of products. The furnaces can be supplied in one complete system conforming to AMS standarts, NADCAP certification, and meeting those tight requirements in terms of temperature uniformity, restrictions for processing time in each step, and all other parameters.

VertiQuench® provides an optimal heat treatment technology for aluminum alloy extruded and drawn porthole or seamless tubes of 2xxx, 6xxx,

Catalogs

No catalogs are available for this product.

See all of SECO/WARWICK DO BRASIL LTDA‘s catalogsOther SECO/WARWICK DO BRASIL LTDA products

Aluminum Furnaces for Heat Treatment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.