- Production - Materials - Metrology

- Surface treatment

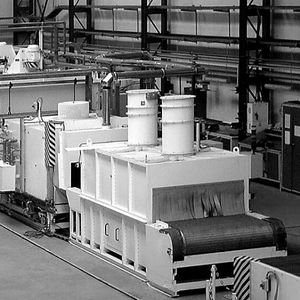

- Chamber furnace

- SECO/WARWICK DO BRASIL LTDA

Chamber furnace CABfor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Other characteristics

- for the aerospace industry

Description

The Universal CAB Batch Furnace provides high aluminum brazing quality for lower volume producers. It is designed to braze the widest variety of heat exchangers in a horizontal or vertical position depending on the product design requirements. It operates on a part-time basis and produced the highest quality parts with the standard or vacuum purge options, respectively. The furnace can be brought up to brazing temperature from ambient and conditioned to a proper atmosphere in a very short time. The batch system allows for variable heating and cooling rates, depending on product requirements.

Two basic types of batch models are available in a variety of configurations in the standard batch CAB plus the optional units using vacuum purging. The commonly used two-chamber atmosphere batch system allows for variable heating and cooling rates, depending on product requirements. One chamber provides purging and cooling in the nitrogen atmosphere while the other chamber is the convection-heated brazing furnace. To get the proper atmosphere parameters, several exchanges of the volume in the entrance chamber is required in the standard batch CAB unit. The same level of an atmosphere can be reached by using a vacuum purging option saving dozens cubic meters of nitrogen per cycle.Two chamber vacuum purging units can also be upgraded later to three chambers unit for economically increasing the output. Other components may be added like degreasing/drying/debinding oven, fluxer, transfer systems, final cooling, and computer controls.

/ Highest flexibility

in part types and brazing position: horizontal or vertical

/ Short preparation time

with only 2-3 hours required

Catalogs

Other SECO/WARWICK DO BRASIL LTDA products

Aluminum Furnaces for Heat Treatment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.