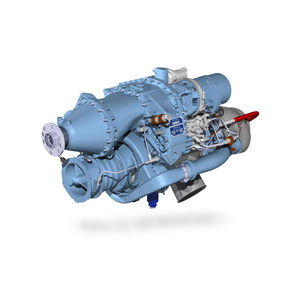

Helicopter turboshaft M250

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for helicopter

Description

Growing the M250’s use in cutting-edge applications

More than 31,000 M250s have been delivered to date for both current and cutting-edge applications, with an estimated 16,000 engines currently in service.

Always reliable, always evolving

Originally developed as the T63 to meet a US Army requirement for a 250 shaft horsepower (SHP) turboshaft, the Series I M250 turboshaft has spawned an entire family of small turbine engines.

A program of continuous development has resulted in today's range of Series II and Series IV engines, which power many of the world's most popular helicopters.

The recently introduced Value Improvement Package (VIP) kit gives Series IV operators a post-production option to improve performance by five percent. A FADEC upgrade program will also deliver improved capability and reliability.

Two-shaft modular design featuring a two-stage LP turbine, two-stage HP turbine, and a gearbox with 6,000rpm output.

Compressed air is routed to the aft end of the engine for combustion, with exhaust gases exiting from the middle of the engine.

The Series II features four to six-stage axial and single-stage centrifugal compressors with a hydro mechanical fuel control system.

The larger Series IV family is identical in layout except for having a single-stage centrifugal rather than an axial/centrifugal compressor.

The latest Series IV turboshafts also feature a FADEC (Full Authority Digital Engine Control) system.

Flexible, innovative and focused on you.

Dedicated to keeping your fleet airborne, no matter where you're based.

With 200 million flight hours and over 50 years of turboshaft experience to our name, Rolls-Royce offers an unparalleled level of service.

Catalogs

No catalogs are available for this product.

See all of ROLLS-ROYCE‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.