- Production - Materials - Metrology

- Materials - Semi-finished products

- Carbon fiber

- Rock West Composites

- Products

- Catalogs

- News & Trends

- Exhibitions

Carbon fiber P-PW-020-11fabric

Add to favorites

Compare this product

Characteristics

- Material

- carbon

- Type

- fabric

Description

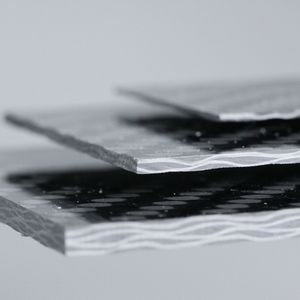

These press molded plates are manufactured using remnant prepregs collected from the commercial aviation manufacturing industry. Rather than discard these remnants in the landfill, the materials are used to manufacture these advanced composite plates made of the highest quality materials. The remnants are too small for the aerospace application that they were purchased for, but large enough to make high quality, high grade carbon fiber plates in a variety of sizes and thicknesses. The result is a cost effective, high performance, and more environmentally friendly solution for plate manufacturing.

We've even got a T1100 carbon fiber variant available! All the plates listed here with a Small Checkered plain weave pattern are constructed of 100% T1100 carbon fiber. This material is also often referred to as "unobtanium" given its highly focused usage to only one or two companies in the world. It touts higher strength and higher stiffness modulus balancing one another to become a proverbial wonder plate!

We've added a 5th plate variant built from upcycled T800 intermediate modulus chip material. This plate is often used in knife, jewelry and pen making as the cross section reveals the unique waviness generally associated with "Forged Carbon Fiber".

Product Details

Material modulus and strength are represented by 5 distinct patterns / weaves;

Standard Modulus Fiber Plate (Fiber: 34 msi | 700 ksi, resin 250F Tg or greater)

2x2 Twill

Plain Weave (3k)

3/8" Medium Checkered Weave / Spread Tow

*T800 Intermediate Modulus Fiber Plate (Fiber: 42 msi | 850 ksi, resin system 3900)

Chip Fiber (particle board / "Forged Carbon") pattern

Chip length ~12mm x 10-12mm

Related Searches

- Fiber

- Aeronautic honeycomb

- Aeronautic prepreg

- Carbon fiber

- Prepreg

- Resin prepreg

- Fabric fiber

- Aluminum honeycomb

- Sandwich panel

- Epoxy resin prepreg

- Honeycomb sandwich panel

- Aeronautic sandwich panel

- Carbon fiber prepreg

- Glass fiber

- Sandwich panel for the aerospace industry

- Aramid paper honeycomb

- Fire-resistant honeycomb

- Flooring honeycomb

- Honeycomb for the aerospace industry

- Prepreg for the aerospace industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.