Quality software SurfitBlade™analysismeasurementdesign

Add to favorites

Compare this product

Characteristics

- Function

- quality, analysis, measurement, design, manufacturing, process

- Applications

- for aeronautics

Description

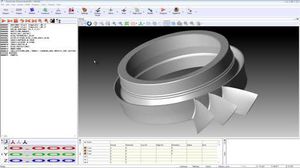

An offline application for use by engineers to generate blade surface forms for use in downstream processes such as computational fluid dynamics and finite element analysis.

As a downstream add on application to APEXBlade, SurfitBlade takes the measurement probe tip-centre data, serialised as a result of running the APEXBlade generated DMIS program through MODUS, and surfaces it. In this way SurfitBlade provides true blade form analysis and radically improves the understanding of manufacturing capability.

SurfitBlade allows design engineers to accurately reverse-engineer manufactured blades, giving them revolutionary new feedback throughout the design and manufacturing process. Complementing APEXBlade, SurfitBlade creates a fully reconstructed surface from tip-centre sweep scan data, serialised as a result of running an APEXBlade generated DMIS program through MODUS. In this way SurfitBlade enables true blade form analysis and radically improves the understanding of manufacturing capability.

SurfitBlade guides you through each stage of the blade reconstruction process:

Sweep scan import

Import sweep scan data from MODUS.out or Geometric Modelling Library .GML files

Set the sweep scan stylus ball radius

Delete any unneeded scans

Surface patch generation

Generate a NURBS surface 'patch' for each of the sweep scans

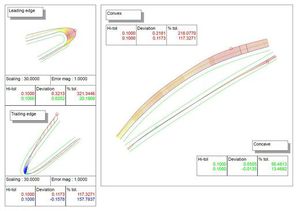

View error plots to gauge the quality of the patches

Adjust the generation criteria to optimise the patches

Section plane generation

Define sectioning planes through the surface patches

Adjust the planes by defining a top and bottom plane at each end of the blade

Catalogs

No catalogs are available for this product.

See all of Renishaw PLC‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.