- Products

- Catalogs

- News & Trends

- Exhibitions

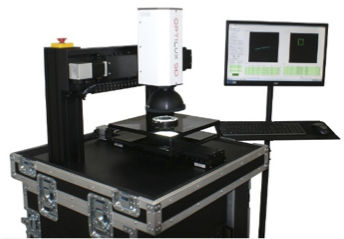

Optical coordinate measuring machine OptiLux SDfor aeronautics

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Probe type

- optical

- Other characteristics

- for aeronautics

Description

Completely objective scratch-dig metrology and optical surface verification system

Our OptiLux Scratch-Dig system has been designed for industrial optics manufacturers who need to precisely evaluate and verify the scratch-dig imperfections of different optic components. It gives complete control of the scratch-dig inspection process by combining a high-resolution sensor head with a precision X-Y motion system to provide a fully-automated, operator-independent surface measurement and analysis routine. This highly repeatable and traceable process delivers a non-disputable scratch-dig quality assurance, as well as limiting the amount of component handling which reduces the risk of accidental damage to fragile surfaces. With the accuracy of repeatable results, technicians can understand how close an imperfection is to the grading boundary, allowing them to refine their production process, for example by knowing exactly when to stop and when to continue polishing in order to meet the surface specification for very fragile surfaces. This immediate automation of the scratch dig inspection process has significant impact on reducing lead times and cost of production.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.