- Production - Materials - Metrology

- Production machine

- Laser welding machine

- PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH

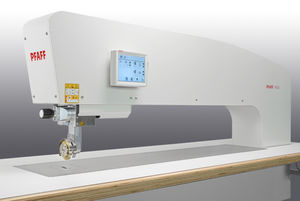

Ultrasonic welding machine PFAFF 8311 Long-armlaserfor aeronautics

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Technique

- laser, ultrasonic

- Other characteristics

- for aeronautics

Description

With the new 8311, PFAFF INDUSTRIAL introduces a new generation of ultrasonic welding machines. With more than 30 years experience in rotary ultrasonic welding, the engineers at PFAFF have successfully developed this process even further. In addition to the regulation of speed and welding energy, the new 8311 allows the force measured during welding to be measured and kept constant - a true world first and a quantum leap in textile ultrasonic welding. Adjusting and handling the machine becomes much easier. The process becomes clearer, more reproducible and easier to understand. In short, the machine is taken to a new level.

Features

1,000 mm arm clearance - for processing voluminous fabrics

Unrivaled attribute: Continuous welding force monitoring!

ALL welding parameter are measured and regulated “speed, energy AND force”

Innovative dual roller system: Cutting wheel can be activated by motor

New: Versatile platform for various options:

- motorized puller

- simple parallel puller

- lighting from above and below (for lower ply visualization)

- seam cooling device (from above and below)

- cross mark laser for precise start position

Smart functions: Seam end detection, ply detection (e.g. cross seams)

New touch screen (simple handling with user-friendly icons)

All proven features of existing ultrasonic machines are included in the new machine concept

Option: motor-driven puller

Applications

Technical section:

Filter bags, health care articles, medical mattresses and pillows, needle felts, operations sheets, foils, bullet proof vests, blinds and awnings, pleated filter, shower curtains, spacer fabrics, seat covers, MBR-modules and many more

Garment section:

Catalogs

No catalogs are available for this product.

See all of PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH‘s catalogsOther PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH products

WELDING MACHINES

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.