- Production - Materials - Metrology

- Production machine

- Aeronautic welding machine

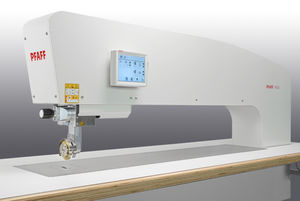

- PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH

Hot air welding machine PFAFF 8320 (D)for aeronautics

Add to favorites

Compare this product

Characteristics

- Technique

- hot air

- Other characteristics

- for aeronautics

Description

Programmable hot-wedge or hot-air welding machine

With the PFAFF 8320 sealing sequences can be programmed, i.e. depending on the cutting and the fabric any parameters can be entered for any given segment and reproduced with 100% accuracy.

An absolute innovation from PFAFF!

"The Transformer......different arms in different length for the PFAFF 8320"

Cylinder post / Swivel post / Vertical post: 470 - 970 mm

Interchangeable swivel unit - easy exchange from hot air to hot wedge or vice versa

Differential transport possible during sealing

No buttons, no pressure gauges: One touch screen and 100% parameter control

All parameters are controlled electronically:

One integrated control board monitors the heat-sealing temperature, the air flow, the roller pressure and the two motors for the top and bottom roller

Proportional valves enable the dynamic adjustment of the air flow and roller pressure

Two precision-controlled motors permit an extremely accurate differential transport

2-axis swing in mechanism:

The nozzle or wedge can be very accurately adjusted without tools by using a compound slide rest

Hinged post: The bottom post holder can be turned over 180° as desired

Depending on the application it is possible to feed off the arm, as post- or feed on the arm

Adjustable stand height: With a crank the working height can be adjusted exactly to suit the application

Different wedge sizes + different nozzle sizes and shapes

Several operating levels protected by passwords: If desired, the operator can only select certain operating sequences

Selectable languages and units of measurement

Heat-up and cool-down cycles possible

Machine can be integrated in a complete production unit

VIDEO

Catalogs

No catalogs are available for this product.

See all of PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH‘s catalogsOther PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH products

WELDING MACHINES

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.