- Production - Materials - Metrology

- Production machine

- Aeronautic welding machine

- PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH

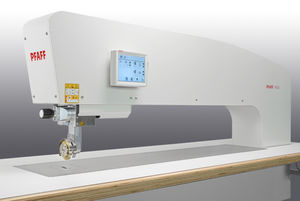

Ultrasonic welding machine PFAFF 8317for aeronauticssingle-phase

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Technique

- ultrasonic

- Other characteristics

- for aeronautics, single-phase

Description

Programmable single-head ultrasonic unit (CS DUAL) with transportation belt system

This solution features two anvil wheels (one for cutting and sealing and the other one to realize the second weld seam) on one post, but on separate shafts. With this patented solution the load may be individually adjusted – the two wheels are still running in sync. This is an absolute unique selling point (USP) for this technology. The machine may be adjusted better and more specifically to the material at hand and increases the process reliability when welding and cutting to weld seams. The minimum distance between weld seam an cutting is around 1 mm.

Features

Cutting and edge sealing or welding on one side of membrane filter plates or technical textiles

Welding procedure: 35 kHz, 400 W ultrasonic generator with rotating 7 mm steel sonotrode or 10 mm titan sonotrode

Control of welding power proportional to welding speed

Two differentiable drives for sonotrode and anvil roll

Weld seam width: Cut & WELD process with cutting wheel or direct welding up to 10 mm seam width

Two differentiable drives for sonotrode and anvil roll

Seam width: Cut & Weld operation with cutting wheel or direct welding up to 10 mm seam width

Applications

Closing of pleated filters, filter bags, filters, sun protection covers, insulation, sunscreen

Specifications

Sealing speed: 0.3 to 10 m/min. option to 20m/min.

Seam width: 1,0 to 10,0 mm

Ultrasonic frequency: 35 KHZ

Connection voltage: single-phase a.c. 230 V, 50/60 Hz

VIDEO

Catalogs

No catalogs are available for this product.

See all of PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH‘s catalogsOther PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH products

WELDING MACHINES

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.