- Production - Materials - Metrology

- Production machine

- Spot welding welding machine

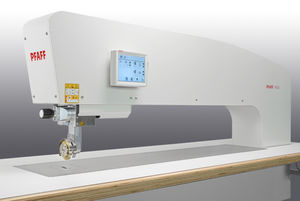

- PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH

Ultrasonic welding machine PFAFF 8310 -041/005spot weldingfor aeronautics

Add to favorites

Compare this product

Characteristics

- Technique

- ultrasonic, spot welding

- Other characteristics

- for aeronautics

- Power

400 W

Description

Programmable ultrasonic welding machine with sonotrode from top, Feed-off-the-arm version (from side)

Ultrasonic welding machines of the Seamsonic series combine all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the PFAFF 8310 Seamtronic the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid changing pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld.

Ultrasonic welding with the Seamsonic is a modern, innovative and economic alternative and complementary to conventional sewing technology. If assembling of laminates, clothing fabrics with high share of polymer and technical nonwovens is required and in particular to get, the use of the Seamsonic is the first choice.

Features

All parameters controlled electronically (power, amplitude, speed and pressure)

Seam distances resp. operating cycles can be programmed (sequence welding)

Reproducibility of the welding process

The energy adjusts to the speed (via a pedal) = Dynamic welding

Equipped with differential feed; separate drive for sonotrode and anvil wheel; that means smooth, non-distorted seams or the possibility of adding a some fullness

Process reliability through monitoring of welding parameters with integrated device for constant performance (so that reliable processing is possible even when sewing over cross seams)

Possibility of spot welding (tacking)

No start/stop – marks

Catalogs

No catalogs are available for this product.

See all of PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH‘s catalogsOther PFAFF INDUSTRIESYSTEME UND MASCHINEN GMBH products

WELDING MACHINES

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.