- Products

- Catalogs

- News & Trends

- Exhibitions

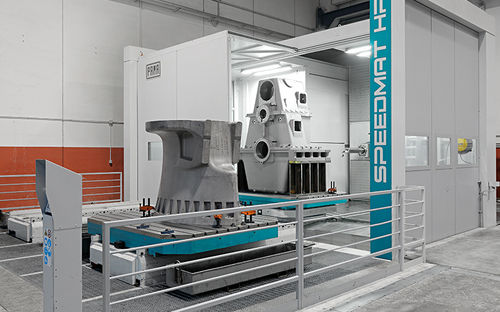

4-axis machining center SPEEDMAThorizontalfor aeronauticsCNC

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- horizontal

- Applications

- for aeronautics

- Other characteristics

- CNC

- Rotational speed

Max.: 4,000 rpm

(25,133 rad.min-1)Min.: 3,500 rpm

(21,991 rad.min-1)- X travel

Max.: 5,000 mm

(196.85 in)Min.: 2,600 mm

(102.36 in)- Y travel

Max.: 3,000 mm

(118.11 in)Min.: 2,000 mm

(78.74 in)- Z travel

Max.: 2,700 mm

(106.3 in)Min.: 2,300 mm

(90.55 in)

Description

PAMA Speedmat boring and milling centers are able to combine maximum rigidity and high precision to satisfy the most difficult applications when machining small- and medium-sized components.

PAMA Speedmat boring and milling centers are distinguished by a T-type structure with a movable column and a travelling table. The column is thermal symmetric with a central headstock for maximum precision.

The structures of the PAMA Speedmat machine were studied using modern finite element state analysis techniques with the purpose of optimising the masses and guarantee high static and dynamic rigidity, as well as greater thermal symmetry.

The headstock includes a mechanical transmission boring bar, with a real time feedback system; PAMA patent.

In line with PAMA’s tradition, the milling machines are equipped with hydrostatic rotating axes to guarantee maximum rigidity and maximum damping while working with capacities up to 25 t.

The versatility of the PAMA Speedmat machine can be increased with a wide range of attachment heads, table pallet systems, including automatic tool and attachment head changing systems.

From a software point of view, the machines can be configured by selecting from among CNC Siemens, Heidenhain and Fanuc.

PAMA Speedmat range provides maximum workpiece diameters from 2600 mm up to 4600 mm and boring bars from 130 mm up to 160 mm.

Related Searches

- Machining machine

- Aeronautic machining center

- CNC machining center

- Aeronautic milling machine

- Milling machine

- CNC milling machine

- Multi-axis milling machine

- Horizontal machining center

- Vertical machining center

- Machining center for the aerospace industry

- 3-axis machining center

- 3-axis milling machine

- Gantry machining center

- 4-axis machining center

- Horizontal milling machine

- Milling machine for the aerospace industry

- 4-axis milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.