Optical inspection system PI 640i G7for materials

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Technology

- optical

- Applications

- for materials

Description

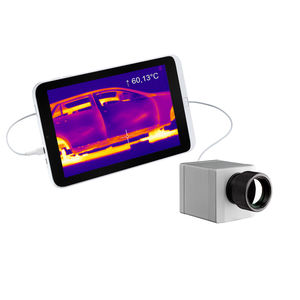

With the new Glass inspection system from Optris, there is a new approach to temperature measurement in the production of low-e glass. Low emissivity glass poses a major challenge for infrared devices which are traditionally measuring the glass temperature from above when the panes moved out of the furnace during production.

The new Bottom Up Glass inspection system solves this problem by having two infrared imagers installed underneath the tempering line which measure the temperature on the non-coated high emissivity side of the glass.

The combination of two VGA imagers with a maximum field of view of 111° results in an excellent 1600 pixels scan line resolution on maximum 4,3 m (14.11 ft) scan width.

An ultra-fast CTlaser 4M pyrometer with 90 µs exposure time combined with the digitally controlled lens protection system (DCLP) is a reliable safeguard for both infrared cameras in case of glass breakage.

Important specifications

Compact bottom up system for coating independent

underneath measurement

Integrated ultra-fast glass breakage detection combined

with Digitally controlled lens protection system (DCLP)

Pre-assembled system for easy installation on glass

tempering furnaces

Glass area calculation

Areas of application for the Bottom Up Glass inspection system

The Bottom Up Glass inspection system solves the problems with temperature measurement of Low-E glass with a new approach.

Areas of application for the Bottom Up Glass inspection system

Le système d'inspection Bottom Up Glass résout les problèmes de mesure de la température du verre Low-E grâce à une nouvelle approche. Installées sous le convoyeur

Catalogs

No catalogs are available for this product.

See all of OPTRIS GMBH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.