Optical inspection system GIS 640 Rautomaticaircraft engine

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Technology

- optical

- Other characteristics

- automatic

- Applications

- aircraft engine

Description

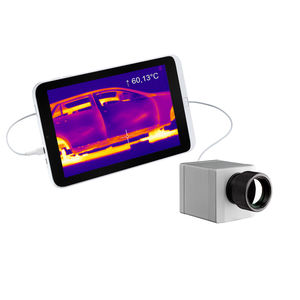

With the new glass inspection system, temperature differences during glass hardening processes can be quickly detected, thus avoiding rejects and providing automatic quality monitoring.

The Top Down GIS 640 R system with temperature referencing by means of a sensor from below as well as automatic emissivity correction for standard and low-E glasses was specially developed for process control in glass tempering machines.

Important specifications

Digitally controlled lens protection system (DCLP) avoids

extra air purging

Glass area calculation

Pre-assembled system for easy installation on glass

tempering furnaces

Automatic scan line adjustment – insensitive to distortions

VIDEO

Catalogs

No catalogs are available for this product.

See all of OPTRIS GMBH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.