- Software - Simulation

- Software

- Test software

- OPEN MIND TECHNOLOGIES AG

Control software hyperMILL® JIG GrindingqualitytestCAM

Add to favorites

Compare this product

Characteristics

- Function

- control, quality, test, CAM, manufacturing, simulation, programming, inspection, process, machining

- Applications

- for aeronautics

- Type

- 3D, 2D

Description

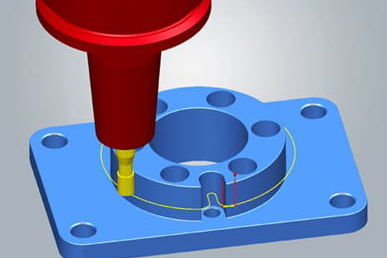

Makes programming milling, drilling, and jig grinding simple with one CAM software: Get the most out of synergies while simplifying NC programming and accelerating the manufacturing process.

Use vertical or conical speed stroke grinding to achieve the best surface quality for your project. The hyperMILL® CAM solution generates the relevant NC programs quickly and reliably using the machine’s control cycle. All the machining parameters for grinding machines and hybrid machines with grinding and HSC milling functions are stored in hyperMILL® and are fed into the NC programming process.

hyperMILL® offers an additional CAM probing module for active process control and component quality inspection. hyperMILL® PROBING enables you to take test measurements using 3D probes directly on the machine. This allows you to manufacture components with incredibly low machining tolerances.

2D contour grinding on a 3D model

Simple and reliable workpiece machining along a contour using 2D contour grinding: Select the contours to be machined and hyperMILL® automatically generates collision-checked toolpaths.

Hole grinding

Hole grinding is programmed the same way as a standard hole. hyperMILL®’s feature and macro technology automatically detect the holes to be ground. This allows you to not only program in record time, but also to tackle your programming tasks comfortably and efficiently.

True-to-detail tool mapping

hyperMILL® provides true-to-detail mapping of tool holders as well as all kinds of grinding references. The CAM software uses this mapping for both simulation and collision checking and takes every relevant technology parameter into account.

Catalogs

No catalogs are available for this product.

See all of OPEN MIND TECHNOLOGIES AG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.