- Production - Materials - Metrology

- Production machine

- CNC milling machine

- Mollart Engineering Limited

- Products

- Catalogs

- News & Trends

- Exhibitions

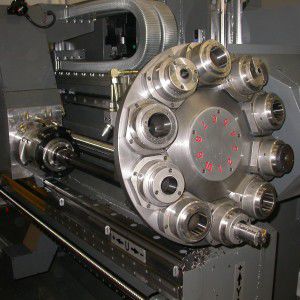

CNC milling machine Centeplexuniversal5-axis or morefor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Type

- CNC

- Spindle orientation

- universal

- Other characteristics

- 5-axis or more, for the aerospace industry

Description

The Centeplex 6-axis combination deep hole drilling machine and conventional machining centre is able to produce deep holes Ø5mm to Ø80mm by up to 2,000 mm in depth while having the capability to perform milling, drilling, boring and threading from an under/over shotgun style secondary spindle.

The spindle arrangement has an in-cycle CNC capability to tilt up to 25° to produce compound angles.

Spindle power is 22 kW and has an ISO50 taper with fully automatic tool changing capability.

The full CNC rotary table size is 2,000mm x 2,740mm and has a maximum weight capacity of 16 tonnes.

Ideally suited for machining of moulds, heat exchanger plates, hydraulic manifolds, cylinders for rolling mills, oil and gas and aerospace components.

Column-type, 6-axis machine

2 spindles with 25º Tilting head

Gundrill Ø5mm to Ø80mm x 2,000mm deep

Rotary table 2,000 x 2,740mm

Compound angle holes

Auxiliary operations such as milling, threading and drilling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.