- Production - Materials - Metrology

- Materials - Semi-finished products

- Rod PPS

- Mitsubishi Chemical Advanced Materials

Plate PPS Techtron® PSGF PPSrodtubeaeronautical

Add to favorites

Compare this product

Characteristics

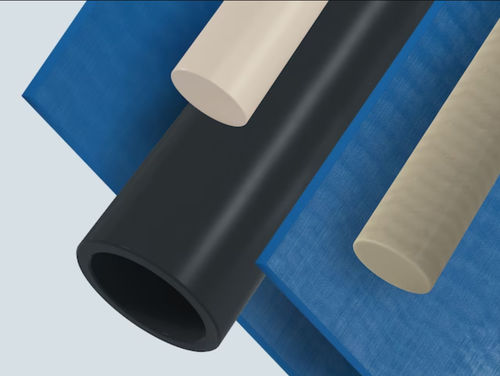

- Shape

- rod, tube, plate

- Other characteristics

- aeronautical

- Operating temperature

Min.: 120 °C

(248 °F)Max.: 230 °C

(446 °F)

Description

Techtron® PPS (polyphenylene sulfide) products close the price and performance gaps between standard and advanced engineering thermoplastics. Our range of Techtron® materials offer the broadest resistance to chemicals of any advanced engineering plastic. They have no known solvents below 200 °C and offer inertness to steam, strong bases, fuels and acids. Minimal moisture absorption and a very low coefficient of linear thermal expansion, combined with stress relieving processes, make these PPS products ideally suited for precise tolerance machined components. In addition, PPS products exhibit excellent electrical characteristics and are inherently flame retardant. These materials are an excellent alternative to PEEK at lower temperatures.

Techtron® PSGF Polyphenylene Sulfide PPS shapes are compression molded and glass filled, giving them extreme dimensional stability as well as improved chemical and corrosion resistance over unfilled PPS materials. Due to these improved performance characteristics, Techtron® PSGF is often chosen as a solution for applications involving critical sealing and structural components, such as pump housings, valves, and compressors within the oil and gas industry.

Material Properties

Compression molded, 40% glass-filled

Improved dimensional stability over unfilled PPS

Improved chemical and corrosion resistance

Techtron® PSBG PPS compression molded shapes are internally lubricated and carbon fiber-reinforced, allowing them to exhibit excellent wear resistance, outstanding dimensional stability, and extreme chemical and corrosion resistance.

Catalogs

No catalogs are available for this product.

See all of Mitsubishi Chemical Advanced Materials‘s catalogsOther Mitsubishi Chemical Advanced Materials products

ADVANCED ENGINEERING PLASTICS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.