- Products

- Catalogs

- News & Trends

- Exhibitions

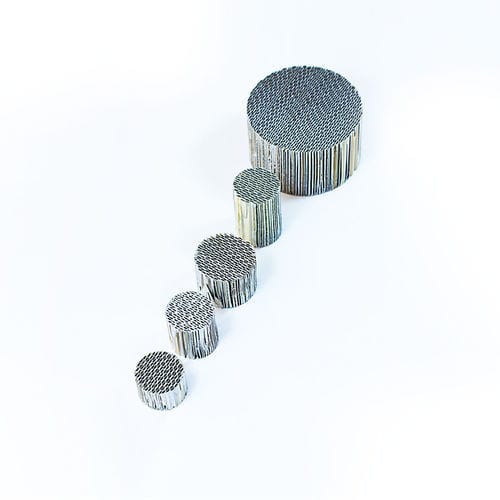

Aluminum honeycomb for aeronauticsfor flooring

Add to favorites

Compare this product

Characteristics

- Material

- aluminum

- Applications

- for aeronautics, for flooring

Description

Miltech International is able to provide you with Honeycomb®, in plate form or in a machined piece according to your plans. But our speciality is the fabrication of parts in Honeycomb® high-density aluminium Higrid 55, more specifically for the fabrication of elements in composite materials.

This material is a non-hazardous product of uniform quality. It presents many other benefits, including very high resistance to deformations. The use of this material reduces the weight without reducing the load capacity.

The inserts are manufactured on demand and are therefore completely suited for their end-use. Their assembly is easy, quick, and does not require handling chemical products. The high density Honeycomb® is used to reinforce edges and fixing points.

ALUMINIUM HONEYCOMB®

The aluminium Honeycomb® of aeronautical standards offered by Miltech International is very light. Of military quality, it is corrosion resistant and offers a superior resistance compared to conventional aluminium composite.

Two alloys are available, both of them meeting the requirements of the MIL-C-7438 standard:

In aluminium alloy 5052

In aluminium alloy 5056

Examples of applications: aircraft and helicopter floors, trailing edges and leading edges of aircrafts’ wings, missiles fins, fans, fuel cells, fuselage elements, helicopter blades, panel mountings…

HIGH DENSITY HIGRID ALUMINIUM HONEYCOMB®

High density Higrid aluminium Honeycomb® is the ideal solution for the manufacturing of mounting inserts and strips for strengthening edges, fields and angles of conventional Honeycomb panels or any other composite structure.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.