- Software - Simulation

- Software

- Maintenance software

- MER Systems Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Reporting software MMSplanningspare parts managementmonitoring

Add to favorites

Compare this product

Characteristics

- Function

- reporting, planning, spare parts management, monitoring, for maintenance

- Applications

- for aeronautics, for airport

- Deployment mode

- web-based

Description

Equipment maintenance management solution to maximise productivity and equipment uptime, generate PM schedules, report and analyse all maintenance activities

MAIN FEATURES

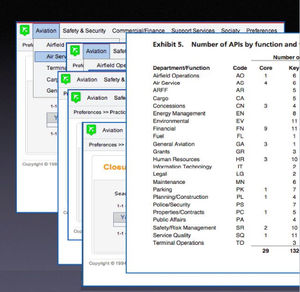

Multiple facilities/plants/rigs/airports/vessels supported

Comprehensive equipment and planned maintenance procedures database

Organise equipment and components into locations, systems, sub-systems, units for easy browsing

Multiple maintenance planing criteria (period, and/or running hours, …)

Failure reporting

Preventive and/or Repair Work Orders

Spare Parts needed/used by Work Order Job

Workforce planning and monitoring by Work Order Job

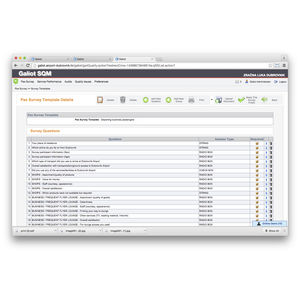

Survey/Certification Management

External Services Management

High level configuration/customisation options

Data import

Fuel and Lub Oil Consumption

WHAT MAKES GALIOT MMS DIFFERENT?

One software, but multiple editions to meet different industries best practice and required regulation (Airports, Airlines, MRO, Marine and Oil & Gas edition)

Integrated with Safety, Audit, Document and Staff Licenses/Training Management modules

Equipment movement (from plant to plant)

Full equipment history (including movements from plant to plant)

Bi-directional asynchronous data exchange (for remote rigs/vessels without or with limited internet access)

Classification societies and Operators Approval

Internal notification, reminder and reporting engine (email and/or text message)

Maintenance Key Performance Indicators identification and monitoring

Accountability by Equipment and/or Job Type

Inventory Management (including spare parts/services requisitioning)

Internal Task Management (Task Request/Assigned/Performed by Department)

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.