- Products

- Catalogs

- News & Trends

- Exhibitions

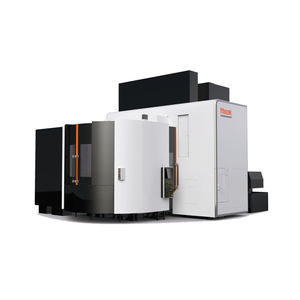

3-axis machining center MEGA 8800horizontalfor the aerospace industryCNC

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- horizontal

- Applications

- for the aerospace industry

- Other characteristics

- CNC, rotating table

- Rotational speed

4,000 rpm

(25,133 rad.min-1)- X travel

1,400 mm

(55.12 in)- Y travel

1,200 mm

(47.24 in)- Z travel

1,325 mm

(52.17 in)

Description

The MEGA 8800 Super High-Torque Horizontal Machining Center is a highly rigid machine that makes the heavy-duty machining of tough materials from steel and cast iron to Inconel and titanium extremely efficient, accurate and productive. The machine features a wide machining area for accommodating large, heavy workpieces.

High-horsepower, high-torque integral spindle/motor

High-rigidity bed and column ensure high-performance, high-accuracy

Linear-roller guides on all axes for speed and accuracy

NC rotary table offers precise four-axis indexing and machining

Cam-driven tool changing ensures reliable high-speed tool change cycles

60-tool storage capacity and 80, 120, 160, 180, 240 and 348 capacities optional

Standard two-pallet changer

Easy interface with Mazak's PALLETECH System for automated

CAPACITY - Maximum workpiece diameter - 1,450 mm

Maximum workpiece height - 1,450 mm

TABLE & PALLET - Pallet width - 800 mm

Pallet length - 800 mm

ATC TOOL MAGAZINE - No. of tool pockets (standard) - 60

Tool shank - MAS BT-50/ BBT-50/ CAT-50/ HSK-A-100

MACHINE SIZE - Width - 3,881 mm

Length - 8,658 mm

Related Searches

- MAZAK machining center

- MAZAK aeronautic machining center

- 5-axis machining center

- MAZAK CNC machining center

- MAZAK horizontal machining center

- Vertical machining center

- MAZAK machining center for the aerospace industry

- MAZAK 3-axis machining center

- Machining center with swiveling spindle

- 4-axis machining center

- Turning center

- Aeronautic lathe

- CNC lathe

- Machining center with moving table

- Lathe for the aerospace industry

- Vertical turning center

- Horizontal lathe

- Rotating table machining center

- Double-column machining center

- 3-axis lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.