- Products

- Catalogs

- News & Trends

- Exhibitions

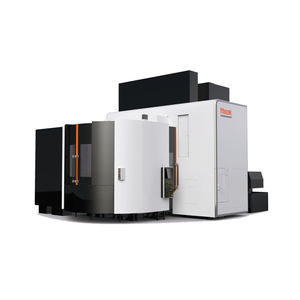

5-axis machining center INTEGREX i-150universalfor the aerospace industryCNC

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- universal

- Applications

- for the aerospace industry

- Other characteristics

- CNC

- Rotational speed

5,000 rpm

(31,416 rad.min-1)- X travel

370 mm

(14.57 in)- Y travel

200 mm

(7.87 in)- Z travel

435 mm

(17.13 in)

Description

Small footprint with exceptional processing versatility

Long Y-axis stroke

Versatile machining and automation with tailstock centre and work handling system

Small footprint with exceptional processing versatility

Compact machine with large machining area

The INTEGREX i-150 is designed with a bar work capacity of Φ65 mm, equivalent to that of a higher class machine, while providing more compact floor space than similar machines with a 6" or 8" chuck with a second spindle. The INTEGREX i-150 is ideal for customers who mainly process small square workpieces and have limited floor space.

Automated system best suited for multi-product processing

Continuous OP10 and OP20 machining thanks to work handling system

The machine is equipped with a work handling system and tailstock unit.

By reversing the workpiece at the unit, continuous OP10 and OP20 machining can be performed.

Machine construction for high-accuracy machining

Long Y-axis stroke

A generous Y-axis stroke of ±100 mm is achieved by using the proven orthogonal Y-axis structure. This provides a wide range for machining.

High-accuracy B-axis positioning

The B-axis is driven by a roller gear cam with no backlash, which can be indexed and positioned in 0.0001° increments.

Closed-loop control with scale feedback system is standard equipment. In addition, Mazak's unique clamping brake system ensures secure positioning and indexing. This ensures stable and high-accuracy positioning for extended periods.

Related Searches

- Mazak machining center

- Mazak aeronautic machining center

- Mazak 5-axis machining center

- Mazak CNC machining center

- Mazak horizontal machining center

- Mazak vertical machining center

- Mazak machining center for the aerospace industry

- Mazak 3-axis machining center

- Gantry machining center

- Machining center with swiveling spindle

- 4-axis machining center

- Turning center

- Aeronautic lathe

- CNC lathe

- Machining center with moving table

- Lathe for the aerospace industry

- Vertical turning center

- Horizontal lathe

- Rotating table machining center

- Double-column machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.