- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP53TCglassfor aeronauticsfor bonding

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Product applications

- for aeronautics, for bonding, glass

- Number of components

- two-component

- Technical characteristics

- conductivity, electrically insulating

Description

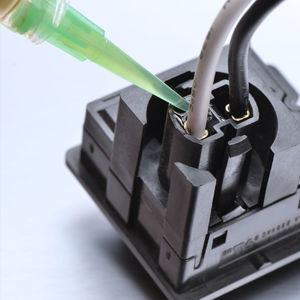

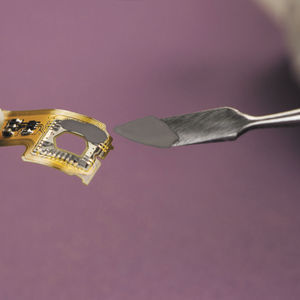

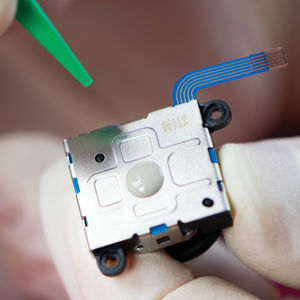

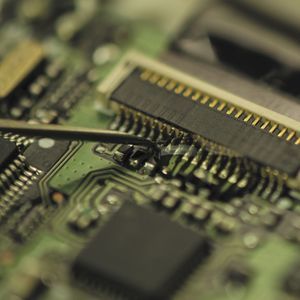

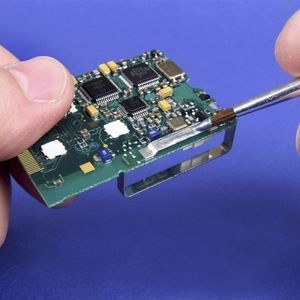

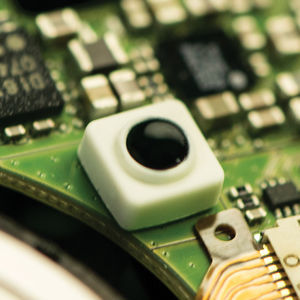

Two part epoxy with high thermal conductivity, electrically insulating, and low thermal resistance for bonding, sealing, coating, and potting

Key Features

Applicable in very thin bond lines

Low thermal resistance

High thermal conductivity >2.0 W/(m•K)

Flowable

Master Bond EP53TC is a thermally conductive, electrically insulating two part epoxy that combines good physical properties and the ability to transfer heat rapidly and effectively. EP53TC has a forgiving 100 to 5 mix ratio by weight. The working life ranges from 6-8 hours. This epoxy cures at 80°C for 2 hours followed by 90-120 minutes at 125°C. An alternative cure schedule would be 4-6 hours at 80-90°C. The hallmark of this system is good thermal conductivity, reliable electrical insulation, and the ability to be used for encapsulation applications.

A special feature of this material is its small particle fillers ranging in size from 5 to 30 microns. When bonding, this allows the epoxy to be applied in especially thin sections resulting in very low thermal resistance. Thermally conductive epoxy usually has a thermal resistance ranging from 30-45 x 10-6 K•m2/W. With EP53TC the thermal resistance is significantly lower because of the high conductivity filler and the ultra small particle size (10-15 x 10-6 K•m2/W). The end result is the epoxy is very effective in transferring heat. The lower the thermal resistance, the better it is for heat transfer properties.

The system bonds well to a wide variety of substrates, including metals, composites, glass, ceramics and many plastics. Other attributes include a very low coefficient of thermal expansion, low shrinkage upon curing and exceptional dimensional stability.

Catalogs

No catalogs are available for this product.

See all of Master Bond Inc.‘s catalogsRelated Searches

- Master Bond adhesive

- Master Bond aeronautic adhesive

- Master Bond epoxy adhesive

- Master Bond bonding adhesive

- Master Bond metal adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond ceramic adhesive

- Master Bond low outgassing adhesive

- Master Bond two-component adhesive

- Master Bond composite adhesive

- Master Bond electrically insulating adhesive

- Master Bond viscosity adhesive

- Master Bond water-resistant adhesive

- Master Bond thermally-conductive adhesive

- Master Bond high-temperature adhesive

- Master Bond single-component adhesive

- Master Bond low-viscosity adhesive

- Master Bond shear strength adhesive

- Master Bond flame-retardant adhesive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.