- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP90FR-HFLfor aeronauticsfor bondingfor metals

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Product applications

- for aeronautics, for bonding, for metals, glass, for plastics, for ceramics, for composites

- Number of components

- two-component

- Technical characteristics

- low-viscosity, electrically insulating, chemical-resistant, flame-retardant

Description

Tested as per Amendment 25-116 and Part 25 Appendix F

Passes horizontal burn test

One to one mix ratio

Withstands 1,000 hours 85°C/85% RH

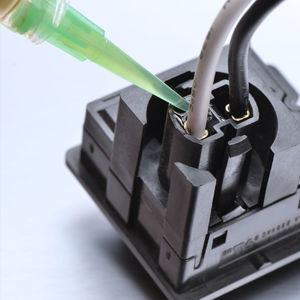

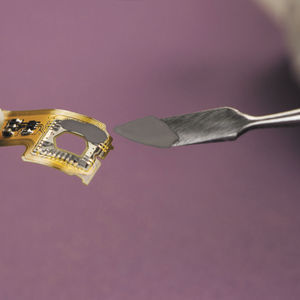

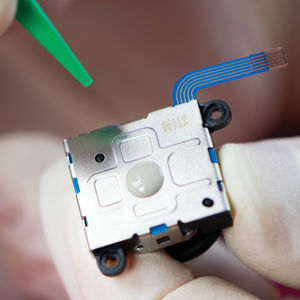

Master Bond EP90FR-HFL is a two component flame retardant epoxy system for bonding, sealing, coating and potting. It has been tested to the standards mentioned above and passes the demanding horizontal burn test specification. Thus, it can be considered for use in many specialized aviation applications. It should be noted that this epoxy is toughened and excels in withstanding rigorous thermal cycling as well as mechanical shock and vibration. Some of the uses include aircraft windows, lighting assemblies and baggage equipment areas, among others. Also, it should be noted that EP90FR-HFL is a non-halogenated type system, which is a big positive regarding handling and environmental issues.

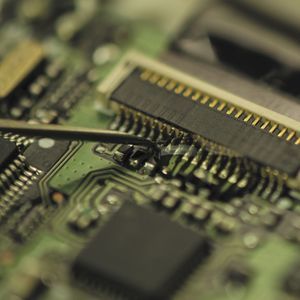

EP90FR-HFL has an easy to use, forgiving, one to one mix ratio by weight. This low viscosity system has a long open time with the recommended curing for optimizing properties being overnight at room temperature followed by 3-4 hours at 150-200°F. Since it is a top notch electrical insulator, it can be a candidate for electronic potting and sealing applications. It bonds well to a variety of substrates including metals, composites, glass, ceramic and many plastics. Since it has some flexibility, it is particularly useful for bonding dissimilar substrates. It has good chemical resistance to water, fuels and oils. The service temperature range is -60°F to +250°F. The color of Part A is black, Part B is white. When mixed, it will turn gray.

Catalogs

Related Searches

- Master Bond adhesive

- Master Bond aeronautic adhesive

- Master Bond epoxy adhesive

- Master Bond bonding adhesive

- Master Bond metal adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond ceramic adhesive

- Master Bond low outgassing adhesive

- Master Bond two-component adhesive

- Master Bond composite adhesive

- Master Bond electrically insulating adhesive

- Master Bond viscosity adhesive

- Master Bond water-resistant adhesive

- Master Bond thermally-conductive adhesive

- Master Bond high-temperature adhesive

- Master Bond single-component adhesive

- Master Bond low-viscosity adhesive

- Master Bond shear strength adhesive

- Master Bond flame-retardant adhesive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.