- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP93AOFR for aeronauticsfor bondingfor metals

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Product applications

- for aeronautics, for bonding, for metals, glass, for plastics, for ceramics, for composites

- Number of components

- two-component

- Technical characteristics

- electrically insulating, thermally-conductive, chemical-resistant, flame-retardant

Description

Tested as per Amendment 25-116 and Part 25 Appendix F

Passes vertical burn test

One to one mix ratio

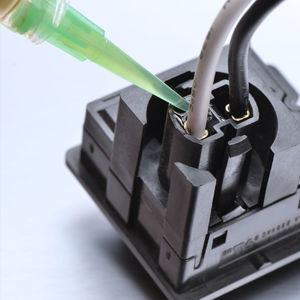

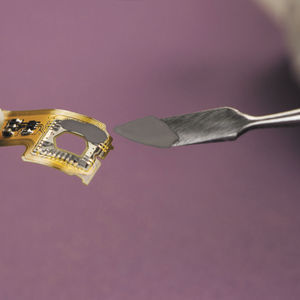

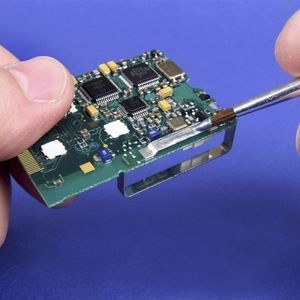

Master Bond EP93AOFR is a two component flame retardant epoxy system for bonding, sealing, coating and potting. It has been tested to the standards mentioned above and passes the demanding vertical burn test. EP93AOFR has an easy to use, forgiving, one to one mix ratio by weight. This system has a long open time. The recommended curing schedule for optimizing properties is overnight at room temperature followed by 3-4 hours at 150-200°F. It is a good thermal conductor while retaining a favorable electrical insulation profile.

It bonds well to a variety of substrates including metals, composites, glass, ceramic and many plastics. The service temperature range is -80°F to +300°F. It has reasonably good chemical resistance to water, fuels, oils and many common solvents. The color of Part A is black, Part B is off white and the cured material is black.

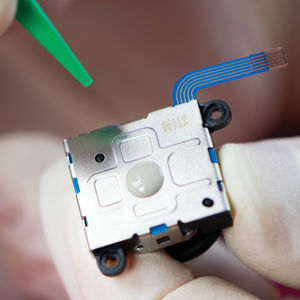

EP93AOFR is a specialty product that is used primarily in avionics. Electronic assemblies such as power conversion units, distribution instruments and cooling devices require first rate protection from flames and heat. Also, they often need to transfer heat to avoid damaging components. EP93AOFR is highly effective in conducting heat and providing protection from flames. It should be noted that EP93AOFR is a non-halogenated system, which is highly desirable for handling and environmental issues.

Product Advantages

Easy to use, forgiving 1:1 mix ratio by weight

Long open time

Good flow properties; can be used for potting

Favorable thermal conductor and electrical insulator

Bonds well to many different substrates

Catalogs

No catalogs are available for this product.

See all of Master Bond Inc.‘s catalogsRelated Searches

- Master Bond adhesive

- Master Bond aeronautic adhesive

- Master Bond epoxy adhesive

- Master Bond bonding adhesive

- Master Bond metal adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond ceramic adhesive

- Master Bond low outgassing adhesive

- Master Bond two-component adhesive

- Master Bond composite adhesive

- Master Bond electrically insulating adhesive

- Master Bond viscosity adhesive

- Master Bond water-resistant adhesive

- Master Bond thermally-conductive adhesive

- Master Bond high-temperature adhesive

- Master Bond single-component adhesive

- Master Bond low-viscosity adhesive

- Master Bond shear strength adhesive

- Master Bond flame-retardant adhesive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.