- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP125for aeronauticsfor bondingfor metals

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Product applications

- for aeronautics, for bonding, for metals, glass, for plastics, for ceramics, for composites, for rubber

- Number of components

- two-component

- Technical characteristics

- low outgassing, viscosity, electrically insulating, chemical-resistant, high-temperature, water-resistant

Description

High glass transition temperature

Meets NASA low outgassing specifications

First rate dimensional stability

Withstands 1,000 hours 85°C/85% RH

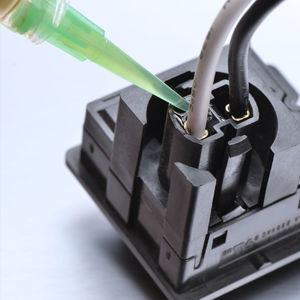

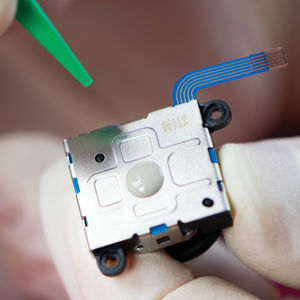

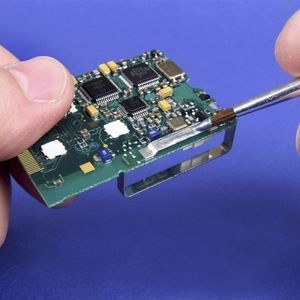

Master Bond EP125 is a special two part epoxy that excels in high temperature applications up to +600°F. Its glass transition temperature is exceptionally impressive; 240-250°C. EP125 has slightly different handling properties when compared to other epoxies, but ultimately, is easily processable. Part A is a moderate viscosity liquid and Part B is a powder. When using this system, Part A is heated to 150-160°F, and then appropriate amount of Part B (based on a 100 to 50 mix ratio by weight) is added and stirred into the heated Part A. The mixed system is a malleable paste, with an exceedingly long open time, that is easy applicable. The curing schedule is 3-4 hours at 300°F or 2-3 hours at 350°F. For optimum properties, post curing for 12-24 hours at 400-450°F is strongly recommended.

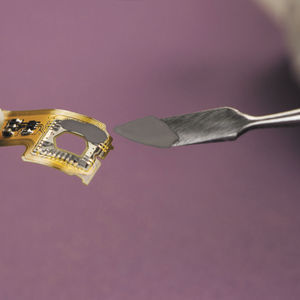

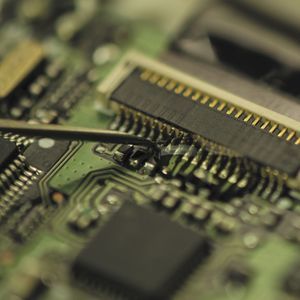

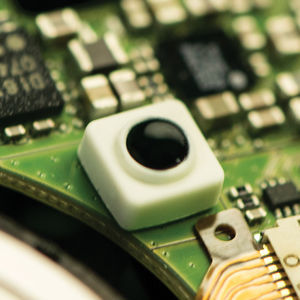

EP125 bonds well to a wide variety of substrates, including metals, composites, glass, ceramics, rubbers and many plastics. Additionally, it is formulated as a toughened system allowing it to withstand rigorous thermal cycling. EP125 is an elite electrical insulator, especially as it retains compelling insulative properties at very high temperatures. Furthermore, it has superb chemical resistance to water, oils, acids, bases and many solvents. There are a few other notable properties, including remarkably high compressive strength, wonderful dimensional stability and low shrinkage upon curing.

Catalogs

No catalogs are available for this product.

See all of Master Bond Inc.‘s catalogsRelated Searches

- Master Bond adhesive

- Master Bond aeronautic adhesive

- Master Bond epoxy adhesive

- Master Bond bonding adhesive

- Master Bond metal adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond ceramic adhesive

- Master Bond low outgassing adhesive

- Master Bond two-component adhesive

- Master Bond composite adhesive

- Master Bond electrically insulating adhesive

- Master Bond viscosity adhesive

- Master Bond water-resistant adhesive

- Master Bond thermally-conductive adhesive

- Master Bond high-temperature adhesive

- Master Bond single-component adhesive

- Master Bond low-viscosity adhesive

- Master Bond shear strength adhesive

- Master Bond flame-retardant adhesive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.