- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP41S-1for aeronauticsfor bondingfor metals

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Chemical composition

- epoxy

- Product applications

- for aeronautics, for bonding, for metals, glass, for plastics, for ceramics, for rubber

- Number of components

- two-component

- Technical characteristics

- low outgassing, low-viscosity, electrically insulating, chemical-resistant, flame-retardant, fast-curing

Description

Ambient temperature cures

100% reactive

Bonds well to a wide range of substrates

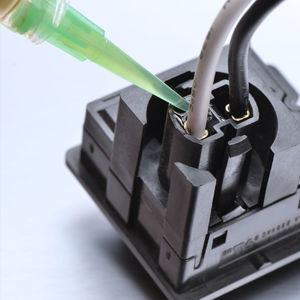

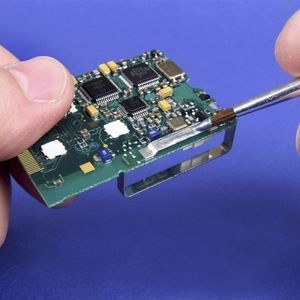

For bonding, sealing and encapsulation

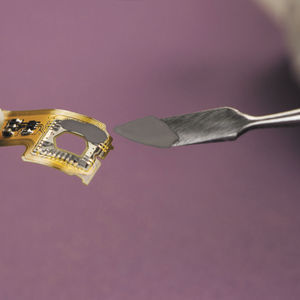

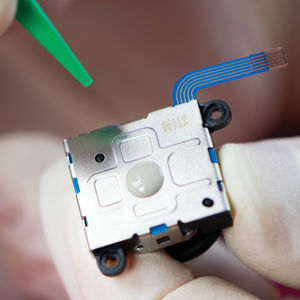

Master Bond EP41S-1 is a two component epoxy resin system for high performance bonding, sealing, coating and encapsulating. It has a 100 to 30 mix ratio by weight and is formulated to cure at ambient temperatures or more quickly at elevated temperatures. It has extraordinary resistance to a wide array of chemicals, including solvents, alcohols and fuels (a more detailed list of these chemicals appears below). Of special significance is its resistance to gasohol, which is fairly aggressive against many types of plastics and rubbers.

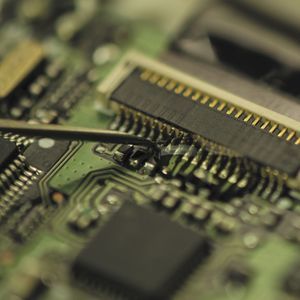

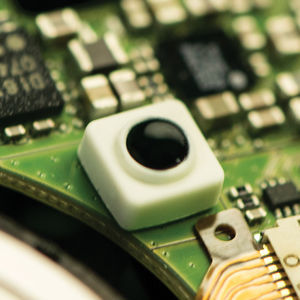

EP41S-1 is 100% reactive and contains no solvents or diluents. It has very low linear shrinkage upon cure. Also, it has outstanding physical properties and electrical insulation values. EP41S-1 can be used as an adhesive, sealant, coating, potting or encapsulating material. It is serviceable over the wide temperature range of -60°F to +300°F. It adheres well to a wide variety of substrates including metals, glass, ceramics and many rubbers and plastics. The standard version of this system has a lower viscosity with good flow. A non-drip version called EP41S-1ND is also available. Part A is clear and Part B is amber clear. This epoxy compound is widely used in aerospace, electronic, chemical processing applications and in other applications where chemical resistance to solvents and fuels is needed.

Product Advantages

Versatile cure schedules; ambient temperature cures or fast elevated temperature cures

High bonding strength to both similar and dissimilar substrates

Wide temperature service from -60°F to +300°F

Catalogs

No catalogs are available for this product.

See all of Master Bond Inc.‘s catalogsRelated Searches

- Master Bond adhesive

- Master Bond aeronautic adhesive

- Master Bond epoxy adhesive

- Master Bond bonding adhesive

- Master Bond metal adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond ceramic adhesive

- Master Bond low outgassing adhesive

- Master Bond two-component adhesive

- Master Bond composite adhesive

- Master Bond electrically insulating adhesive

- Master Bond viscosity adhesive

- Master Bond water-resistant adhesive

- Master Bond thermally-conductive adhesive

- Master Bond high-temperature adhesive

- Master Bond single-component adhesive

- Master Bond low-viscosity adhesive

- Master Bond shear strength adhesive

- Master Bond flame-retardant adhesive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.