- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP21TCHT-1for aeronauticsfor bondingfor composites

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Product applications

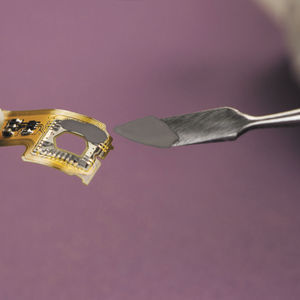

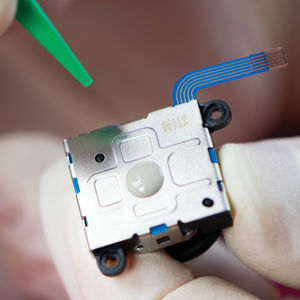

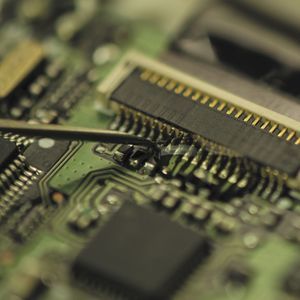

- for aeronautics, for bonding, for composites, for metals, for plastics, glass, for ceramics, for rubber

- Number of components

- two-component

- Technical characteristics

- low outgassing, dimensionally stable, electrically insulating, thermally-conductive, high-temperature

Description

Cryogenically serviceable

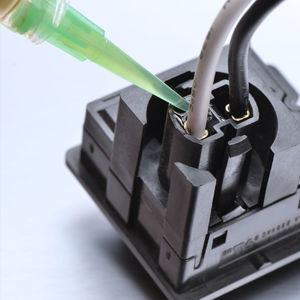

Easy to apply, paste consistency

Withstands 1,000 hours 85°C/85% RH

Master Bond EP21TCHT-1 is a two component, thermally conductive, heat resistant epoxy compound formulated to cure at ambient temperatures or more rapidly at elevated temperatures. EP21TCHT-1 has a 100:60 mix ratio by weight. Most significantly, it passes NASA low outgassing tests with exceptionally sterling numbers. EP21TCHT-1 offers an array of outstanding physical properties once cured. The system is an excellent, high strength adhesive that conducts heat, yet is electrically insulative. This epoxy can withstand rigorous thermal cycling and shocks. It is highly distinctive in that it possesses high temperature resistance as well as superlative cryogenic serviceabililty. Its actual service temperature range is from 4K to +400°F. It bonds well to a wide variety of substrates, including composites, metals, ceramics, glass and many rubbers and plastics. EP21TCHT-1 resists many chemicals including water, oils, fuels and many acids and bases. Its thermal expansion coefficient is remarkably low, as indicated below. For an epoxy system, its dimensional stability is second to none. The color of Part A and Part B is off-white. EP21TCHT-1 is widely used in aerospace, electronics, electrical, semiconductor, and cryogenic applications. As a NASA qualified system, it is ideal for high vacuum type applications, particularly those where only slightly elevated temperature cures are possible. However, the best curing schedule to optimize properties is overnight at room temperature followed by 2 hours at 175-200°F.

Product Advantages

Easy to apply paste consistency

VIDEO

Catalogs

Related Searches

- Master Bond adhesive

- Master Bond aeronautic adhesive

- Master Bond epoxy adhesive

- Master Bond bonding adhesive

- Master Bond metal adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond ceramic adhesive

- Master Bond low outgassing adhesive

- Master Bond two-component adhesive

- Master Bond composite adhesive

- Master Bond electrically insulating adhesive

- Master Bond viscosity adhesive

- Master Bond water-resistant adhesive

- Master Bond thermally-conductive adhesive

- Master Bond high-temperature adhesive

- Master Bond single-component adhesive

- Master Bond low-viscosity adhesive

- Master Bond shear strength adhesive

- Master Bond flame-retardant adhesive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.