- Production - Materials - Metrology

- Production machine

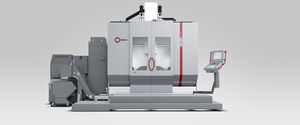

- 3-axis machining center

- MASCHINENFABRIK BERTHOLD HERMLE AG

3-axis machining center C 12verticalfor aeronautics

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Applications

- for aeronautics

- Rotational speed

Min.: 12,000 rpm

(75,398 rad.min-1)Max.: 42,000 rpm

(263,894 rad.min-1)- X travel

350 mm

(13.78 in)- Y travel

440 mm

(17.32 in)- Z travel

330 mm

(12.99 in)

Description

Maximum efficiency combined with a installation area: The C 12 is the most compact Hermle machining centre in the High-Performance-Line. Designed for machining cubic parts up to 100 kg in weight, the

C 12 works in the most diverse applications compactly, precisely and dynamically. As the following application areas show, the right RPM rating is available for practically any application.

The especially compact and space-saving C 12 machining centre meets the ever increasing demands placed on speed and precision thanks to the corresponding Hermle setups. It goes without saying that there are also many options available for more complex situations. You can discover more details about the C 12 via the i-buttons in the 360 degree view.

They’re as reliable as a goalkeeper on his line, and as precise as a golfer’s putt – our machining centres prove their star qualities in all kinds of different industries whenever efficient and powerful milling and turning are needed. Get the best results, and make it to the top in all kinds of disciplines! To the video…

HIGH-TECH TOOL SPINDLES WITH COLLISION PROTECTION

The slimline tool spindles are constructed in two parts and can be replaced easily and quickly during servicing. Thanks to low interfering edges and collision protection by compression sleeves, safety is given primary importance by maximum collision avoidance. Damage can be prevented in 50 % of collisions.

Other MASCHINENFABRIK BERTHOLD HERMLE AG products

Machining centres

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.